The world of tube manufacturing is present process a deep transformation, and at its core is the pursuit of precision and effectivity. Modern inspection programs are taking part in a pivotal position on this revolution, enabling producers to embrace the way forward for welding expertise.

On this weblog, we’ll discover the evolution of Excessive-Frequency Induction (HF) welding and the way expertise is shaping its future.

HF welding is famend for its pace and flexibility, making it a well-liked selection for producers coping with varied tube diameters and thicknesses. Nonetheless, it presents producers with advanced challenges. Exact management over mill geometry, materials high quality, and welder settings is important. Because the demand for high-strength supplies and cost-effective manufacturing rises, producers want an answer to beat these challenges.

On the coronary heart of this transformation is the mixing of superior inspection programs, designed to deal with the intricacies of HF welding whereas maximizing precision and effectivity.

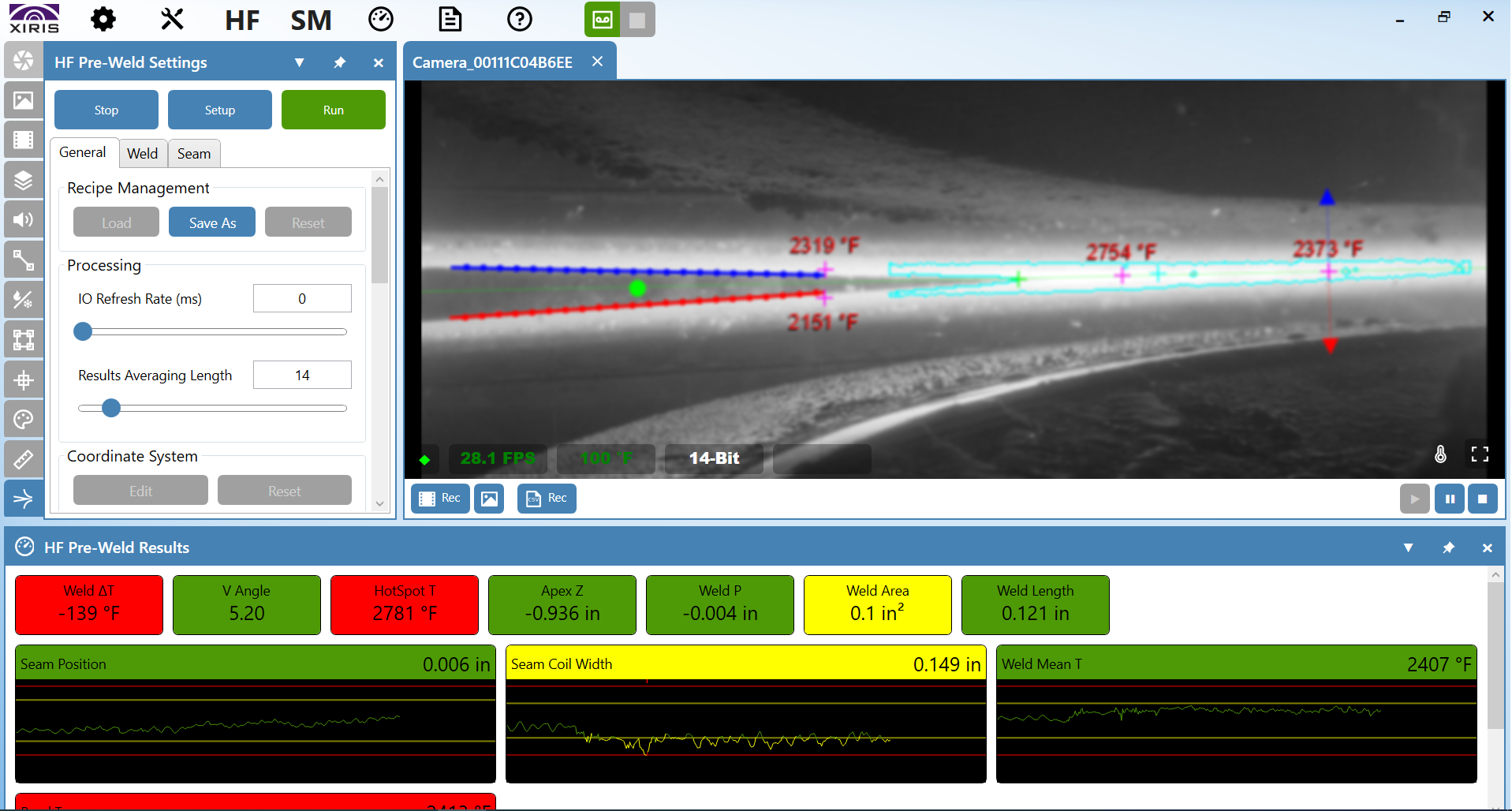

- Unprecedented Readability: Superior cameras supply an in depth 2D view of the Weld “V” post-induction coil, offering operators with invaluable insights into the welding course of.

- Knowledge-Wealthy Evaluation: These programs decode each geometric and thermal information, empowering producers to attain exact management over each facet of the welding course of.

- Actual-Time: Steady measurement and real-time monitoring allow operators to fine-tune the welding course of because it unfolds, responding to adjustments swiftly.

- Knowledge-Pushed Resolution-Making: Statistical Course of Management (SPC) evaluation instruments guarantee data-driven excellence, setting the business’s new commonplace for high quality.

A Screenshot of the Course of Display Taken from the System Laptop (supply: Xiris) A Screenshot of the Course of Display Taken from the System Laptop (supply: Xiris) |

A crucial query in HF welding revolves round measuring the V-angle. This parameter performs a pivotal position in figuring out the welding course of’s effectivity and reliability. Modern inspection programs present a transparent reply to this question, providing real-time measurements and insights that information operators to attain the optimum V-angle.

With these superior inspection programs in place, the business has witnessed a outstanding transformation:

- Seamless Welds: Flawless welds and unwavering high quality have grow to be the business’s new norm, elevating the bar for high quality requirements.

- Value-Effectivity: Enhanced productiveness and cost-efficiency have grow to be the business’s new norm, permitting producers to satisfy market calls for successfully.

- Actual-Time Management: Operators now have the flexibility to fine-tune the welding course of in real-time, responding to adjustments swiftly.

- Knowledge-Pushed Excellence: Knowledgeable selections primarily based on information have grow to be the cornerstone of operations, making certain optimum outcomes.

- Early Deviation Detection: The business now boasts early detection of deviations, permitting for quick corrective actions and sustaining constant high quality.

The mixing of progressive inspection programs has ushered in a brand new period of precision and effectivity in tube manufacturing. The business is not certain by the restrictions of the previous, and the long run appears extremely promising.

Obtain our unique whitepaper, delving deeper into mastering HF welding challenges and attaining precision in tube manufacturing. Be taught all in regards to the “V”, measuring the seam hole, the “V” size, weld size, finding the apex, measuring temperature of different options, and use the gathered information.

Keep updated by following us on social media or subscribe to our weblog!

![]()

![]()

![]()

![]()