Suppose you may have a manufacturing line getting used to fabricate steel components. At each stage of manufacturing, there are high quality assurance steps you must comply with and utilizing machine imaginative and prescient to unravel them known as machine imaginative and prescient inspection.

Chances are you’ll must examine the width, peak, and depth of each element, making certain it meets exact measurements. You’ll want to determine defects (i.e. scratches) so your clients all the time obtain the best high quality merchandise.

In trendy manufacturing services, machine imaginative and prescient is on the coronary heart of high quality assurance processes. You need to use cameras and software program to make sure {hardware} in your meeting line meets your requirements for high quality. You possibly can measure objects, determine attributes or defects, determine merchandise whose shade is just not appropriate, and extra.

For instance, here’s a machine imaginative and prescient system that identifies knots in wooden:

On this information, we’re going to talk about what machine imaginative and prescient is and the way machine imaginative and prescient is utilized in manufacturing services. With out additional ado, let’s get began!

What’s Machine Imaginative and prescient?

Machine imaginative and prescient refers to know-how that you should use to guarantee the standard of merchandise and determine defects. Machine imaginative and prescient applied sciences are visible, requiring the usage of a digital camera. The photographs or video frames from a digital camera are then analyzed utilizing varied machine studying strategies.

Machine imaginative and prescient is used to:

- Establish the colour of a product;

- Establish the presence of defects in a product;

- Measure the size, width, and depth of a product;

- Examine the define of a product to a reference, and extra.

That is performed by making a linked system of {hardware} and software program that’s built-in instantly into a producing or high quality assurance course of. For instance, you may need a digital camera pointed over merchandise as they undergo an meeting line to measure defects. You may need a barcode detection system that factors along with bins to be used in recording when a product has reached the top of the meeting line and is able to be shipped.

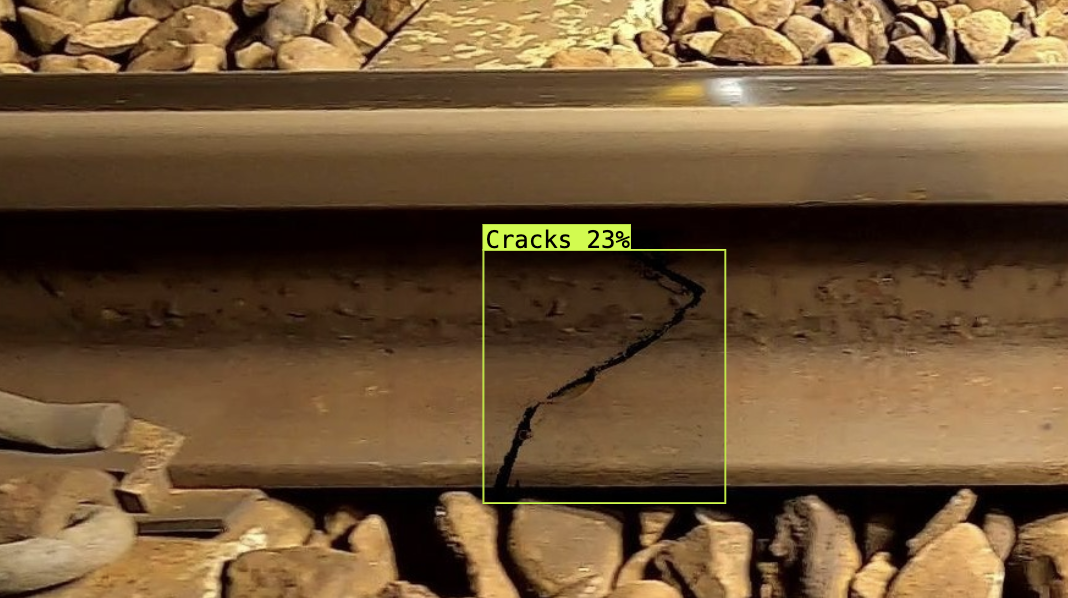

Machine imaginative and prescient is utilized by a variety of sectors. For instance, producers use machine imaginative and prescient to guarantee the standard of merchandise. Important infrastructure suppliers resembling railroads use machine imaginative and prescient to observe for security hazards resembling cracks in rails and wheels. Textiles firms use machine imaginative and prescient to make sure merchandise use the precise colours.

Classes of Machine Imaginative and prescient

Machine imaginative and prescient might be break up in two classes: conventional and deep studying.

In conventional machine imaginative and prescient programs, digital camera feeds are analyzed to determine edges in merchandise, product shade, the size of a product, and different attributes of curiosity. That is performed utilizing handbook algorithms. Conventional programs typically make use of purpose-built {hardware} for figuring out explicit attributes. For instance, you may need a digital camera that analyzes the colour of a product or a barcode scanner that assures the standard of a barcode.

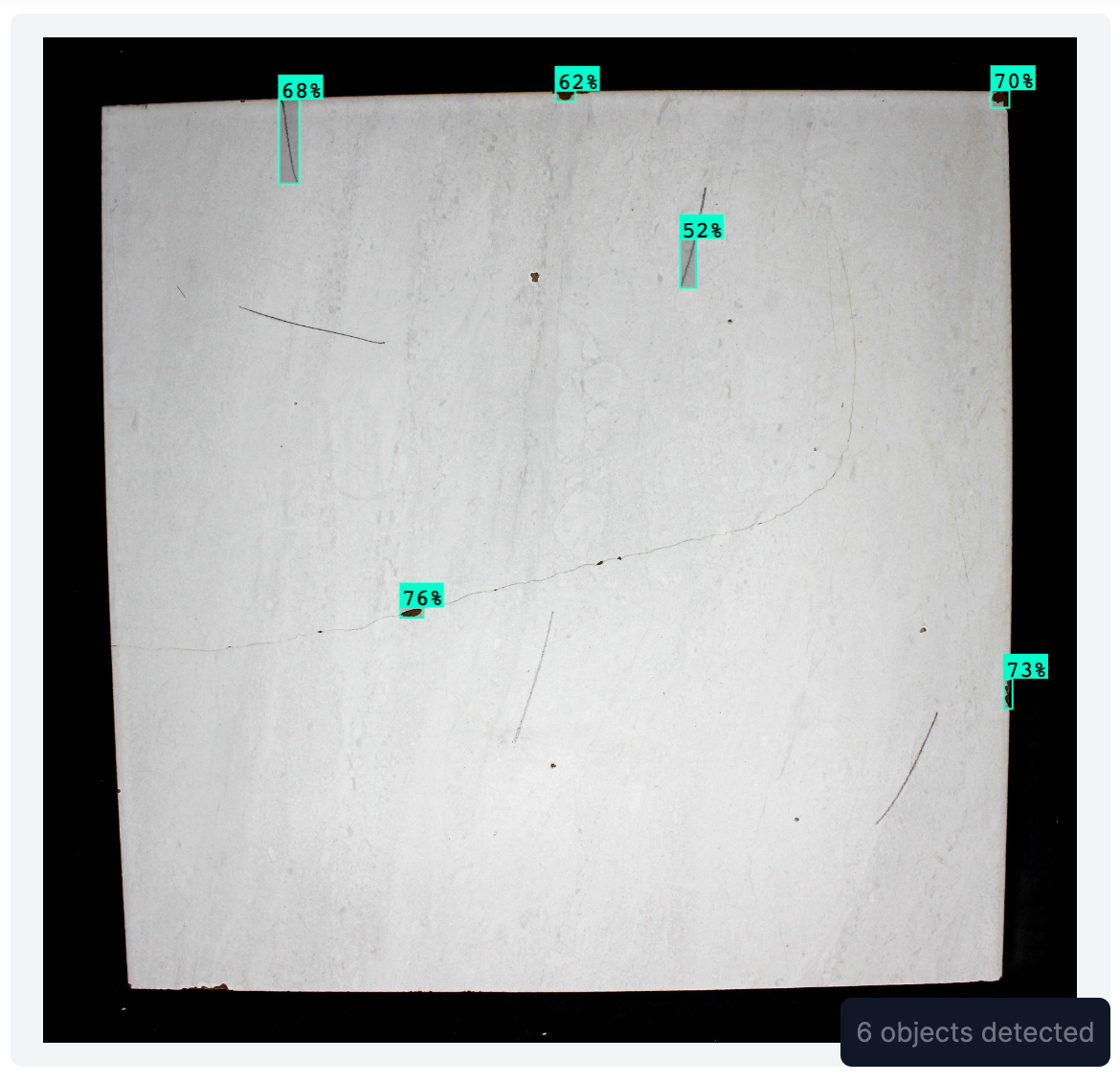

In recent times, deep studying approaches have change into extra widespread, enabling firms to construct multipurpose and adaptive high quality assurance programs. For instance, you should use object detection, a subset of deep studying, to determine the precise location of various defects. Suppose a steel half can have a scratch, a chip, and a dent. You need to use object detection to determine defects and their location on a product. You possibly can then assign labels – “scratch”, “chip”, “dent” – to every defect. This may be performed in a few hours with round 100 photographs.

Within the picture beneath, each chip in a bit of ceramic materials is highlighted with a blue field and a confidence stage. The arrogance stage signifies the probability {that a} crack is current.

Deep studying programs might be deployed on edge gadgets resembling an NVIDIA Jetson or a Raspberry Pi, or consumed by a central server that your group maintains that processes all digital camera feeds.

Deep studying programs might be built-in with the remainder of your manufacturing course of. For instance, you might arrange a defect detection system to observe for high quality points that span your total meeting line or you possibly can monitor the incidence fee of defects at totally different stations.

This information can then be analyzed to seek out the place defects are mostly recognized. When you already know from the place defects emerge, you possibly can allocate time to diagnose and resolve points (i.e. conduct an inspection of a selected machine).

Construct a Machine Imaginative and prescient System

Machine imaginative and prescient programs might be tailor-made to your particular enterprise necessities. For deep studying primarily based approaches, that you must prepare a pc imaginative and prescient mannequin and develop logic that enforces your small business necessities. There are 4 kinds of pc imaginative and prescient mannequin:

- Object detection, which includes discovering the placement of an object of curiosity in a picture;

- Keypoint detection, which identifies key factors in an object (i.e. corners);

- Segmentation, which is used to determine, to the pixel stage, the place an object is situated in a picture, and;

- Classification, which is used to assign a number of labels to a complete picture (i.e. faulty vs. not faulty).

You need to use a platform like Roboflow to construct a machine imaginative and prescient system. Utilizing Roboflow, you possibly can annotate photographs, discover the information you may have collected to be used in coaching a mannequin, prepare a mannequin, consider your fashions, and deploy your fashions to the sting.

Giant enterprises throughout industries use Roboflow to implement pc imaginative and prescient options to unravel enterprise issues. For instance, Roboflow is utilized by Rivian Automotive, Medtronic, USG, and Cardinal Well being for machine imaginative and prescient to fulfill their enterprise targets.

To study extra about how one can develop a machine imaginative and prescient answer in your group, contact our gross sales staff.

Conclusion

Machine imaginative and prescient refers to applied sciences which can be used to know visible information. The time period “machine imaginative and prescient” is often used to consult with conventional strategies to investigate the information gathered by cameras. This consists of analyzing edges, figuring out product colours, measuring the size of merchandise, and extra.

Over the previous couple of years, pc imaginative and prescient strategies have expanded and simplified methods to make use of machine imaginative and prescient. Pc imaginative and prescient strategies use deep studying to determine properties in objects. You possibly can determine product defects, determine key factors in a picture, and classify photographs. You possibly can construct your personal ontology to determine precisely the defects that have an effect on your merchandise. All of that is performed utilizing machine studying which supplies you extra flexibility than rules-based conventional machine imaginative and prescient strategies.

After getting a pc imaginative and prescient answer in place, you possibly can combine it with your small business logic. You possibly can mechanically reject merchandise that show a defect or monitor what machines end in greater incidence charges of defects or determine when no merchandise are current on an meeting line, indicating a fault.