In tube and pipe manufacturing, security and course of stability are essential. A North American pipe producer partnered with Xiris to supply real-time visibility of the weld V whereas making certain operator security. They applied an HF Pre-Weld Inspection System with a customized digicam and software program instruments, leading to enhanced security and course of stability.

The Problem:

A big North American pipe producer was fascinated with offering their operations employees with a distant view of the weld V throughout run time, as a security enchancment in order that the operator doesn’t should climb on the mill to see the method.

As well as, if the digicam may present a transparent view of the weld V that might be monitored remotely, quite than making an attempt to look by means of the steam generated within the mill, would allow their operators to work towards a “palms off” welding course of, lowering the necessity for operators to succeed in into the weld atmosphere to make checks or changes of the welding course of.

Key Goals:

The pipe producer was most to look at some mechanical variations of their course of, particularly:

- Respiratory on the V hole, or a cyclical instability of the tube of the house between the 2 strip edges simply after the induction coil. Such a phenomenon might be the results of imperfect forming rollers, various stresses alongside the pipe or variances within the warmth going into the tube;

- Place of the weld apex because it pertains to the weld squeeze level. The weld apex is outlined to be the purpose on the tube the place the 2 strip edges of the tube come collectively and first contact. Its location is a results of a variety of elements together with the V angle, the forming roll place and stress and inductive power flowing into the pipe;

Buyer Success:

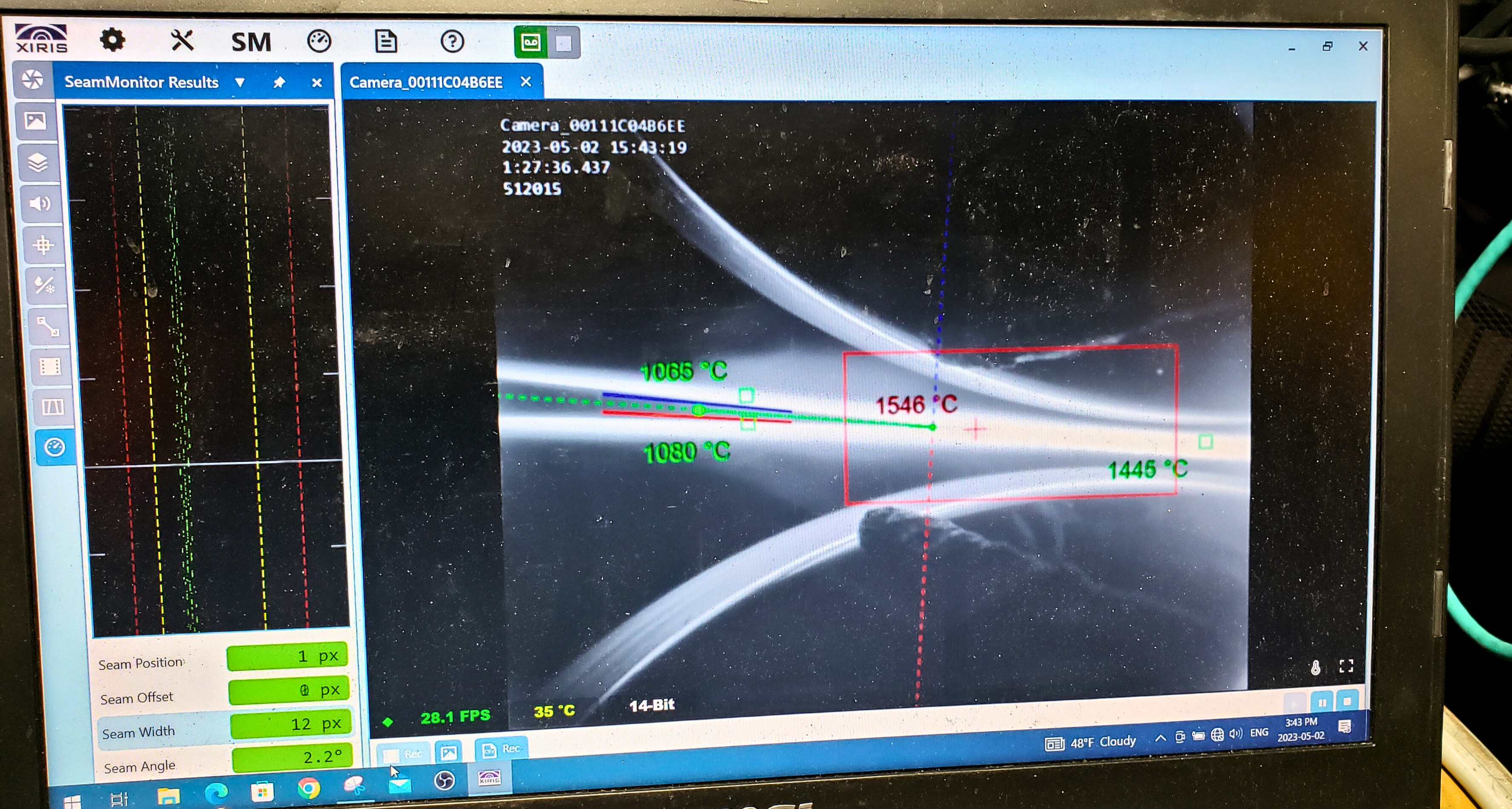

A Xiris SWIR thermal digicam was encased in a specifically designed housing and positioned on the HF weld atmosphere to have a look at the weld “V” instantly after the induction coil. The housing was designed to make use of air move to make sure that no steam, smoke or different particulates would attain the digicam optics and intervene with the picture.

Course of tailor-made software program instruments have been applied for ease of use by the weld operator to detect the weld apex and any respiration that would happen within the seam hole on the pipe.

Display shot of the weld V space

By using picture processing software program instruments, the operator was in a position to get course of suggestions and set working vary limits that would set up greatest practices. The aim of giving the operator measurable course of suggestions with alarms was achieved in order that the operator receives early indicators of any course of anomalies.

Outcomes and Advantages:

The implementation of the HF Pre-Weld Inspection System led to important outcomes and advantages:

-

Enhanced Security: The distant monitoring answer offered a safer strategy to overseeing the weld course of, lowering the potential for operator accidents related to bodily inspections.

-

Improved Stability: The pipe fabricator achieved a extra steady welding course of, ensuing within the manufacturing of constantly high-quality merchandise. By addressing mechanical variations and intently monitoring the weld parameters, the method grew to become extra predictable and dependable.

In partnership with Xiris, the pipe producer within the tube and pipe business efficiently enhanced weld course of security and stability. The combination of an HF Pre-Weld Inspection System geared up with specialised digicam expertise and software program instruments not solely mitigated security dangers but additionally ensured higher course of consistency. This case research underscores the worth of innovation and expertise in attaining operational excellence and security in manufacturing.

To be taught extra about how one can implement Xiris inspection methods, attain out to our product consultants.

Keep updated by following us on social media or subscribe to our weblog!

![]()

![]()

![]()

![]()