Verifying the integrity of steel components throughout manufacturing is important. Relying on the steel half, there could also be a variety of defects current: scratches, dents, or in any other case undesirable blemishes.

You should utilize pc imaginative and prescient to determine steel defects. Laptop imaginative and prescient can be utilized to determine the precise defects current on the components with which you might be working, or the components you might be manufacturing. This lets you construct a system on which you’ll depend upon for defect detection and high quality assurance processes.

On this information, we’re going to stroll by means of easy methods to defect steel defects with pc imaginative and prescient. We are going to present you easy methods to use a pre-trained pc imaginative and prescient mannequin to detect defects. We are going to then discuss how one can prepare your individual mannequin and combine pc imaginative and prescient into your system.

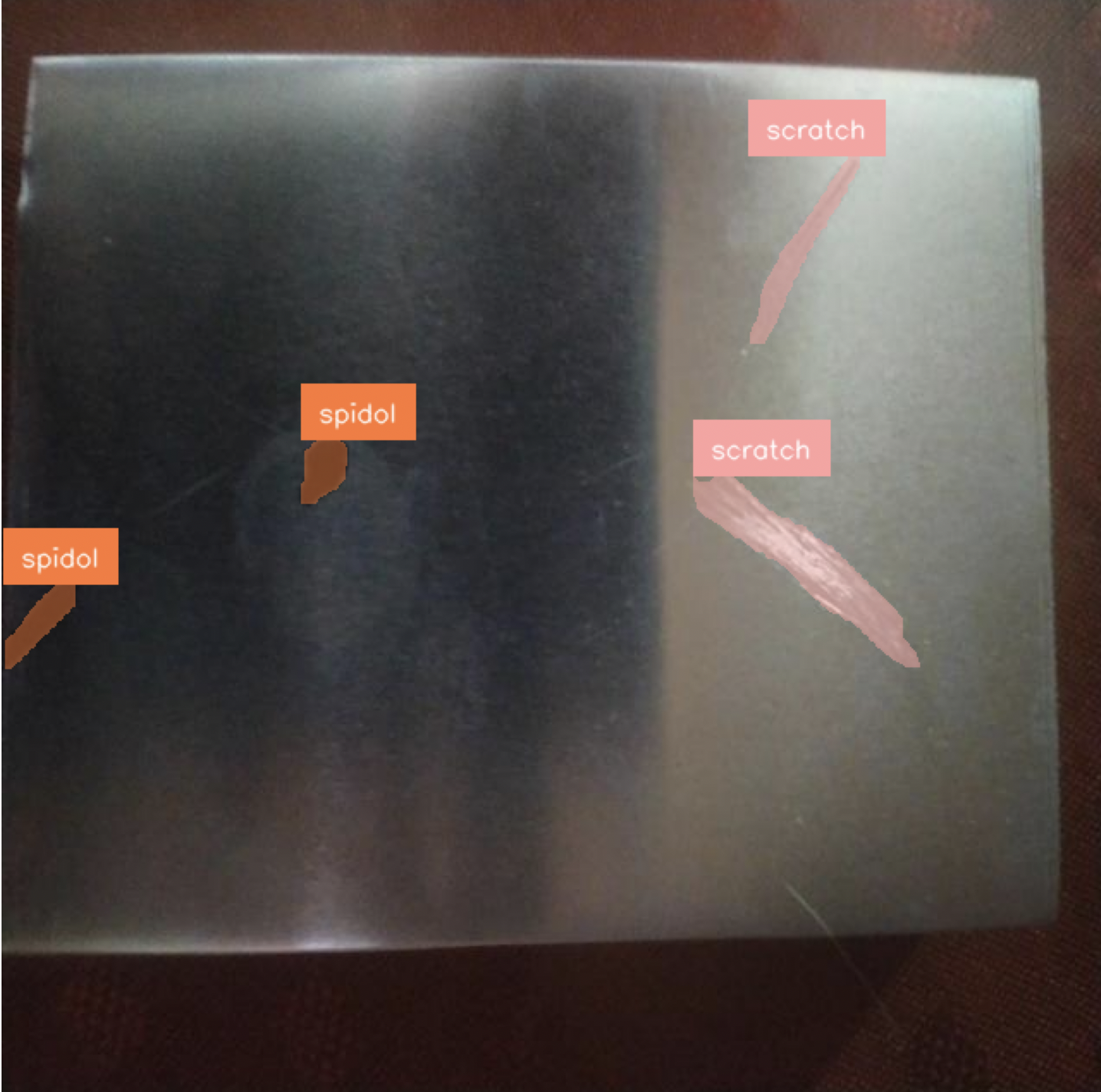

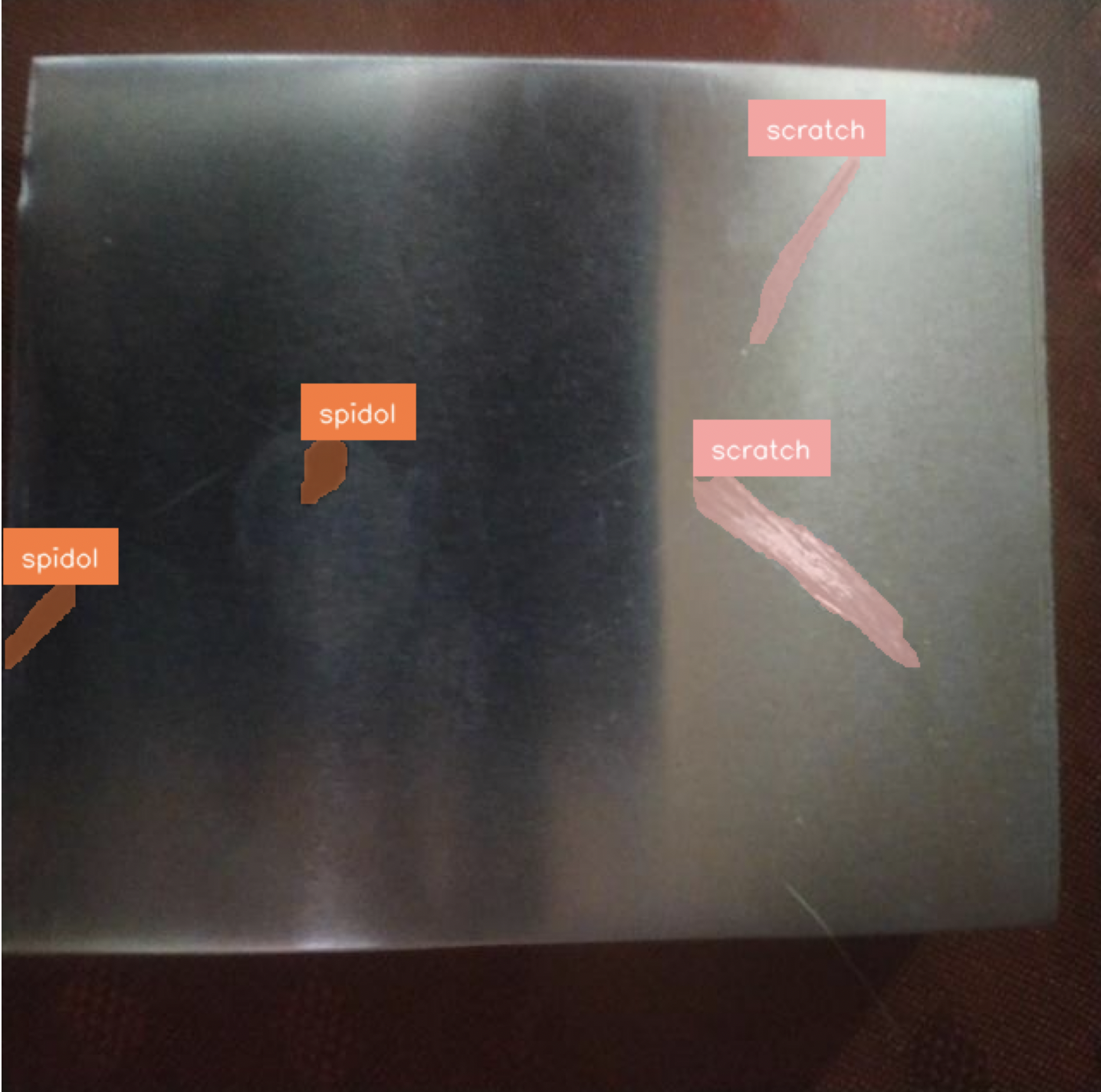

Right here is an instance of our system in motion:

With out additional ado, let’s get began!

Conventional machine imaginative and prescient methods use instruments like sample matching to determine the presence of steel defects. These methods, whereas dependable, often do one test at one time. Because of this a component could need to go by means of a number of cameras to run the required checks.

Laptop imaginative and prescient methods, then again, use deep studying to determine options in an object. For instance, you may prepare a system to determine – and distinguish between – dents, cracks, and scratches. This method can run in actual time, like machine imaginative and prescient methods, and be linked to a producing execution system to be used in monitoring a manufacturing line.

Laptop imaginative and prescient is an efficient technique to determine steel defects. To construct a pc imaginative and prescient system to determine steel defects, you want a mannequin that may determine defects. A mannequin is a sort of pc program that has been skilled to seek out particular objects.

On this information, we’re going to present you easy methods to use a pre-trained pc imaginative and prescient mannequin. This mannequin is prepared to be used out-of-the-box. We are going to then discuss how one can prepare your individual mannequin to determine the precise defects current in your manufacturing facility.

Step #1: Create a Roboflow Account

We’re going to use the Roboflow platform to deploy our imaginative and prescient mannequin. To get began, create a free Roboflow account. This can permit you to entry an API key which we are going to use to check a pre-trained defect detection mannequin.

Open the steel defect detection mannequin on Roboflow Universe. Universe is the world’s largest group of open supply pc imaginative and prescient fashions, with over 50,000 pre-trained fashions accessible to be used.

To check the mannequin, click on “Mannequin” within the sidebar. Then, select a picture from the left pane on the display screen labeled “Take a look at Set”. This can permit you to check the mannequin on a picture that has been put aside to be used in testing mannequin efficiency. You can too add your individual picture or video to make use of on the mannequin.

Within the picture above, our mannequin efficiently recognized floor defects. “spidol” marks discolorations recognized on the surfac.

Step #3: Deploy the Mannequin

All fashions skilled on Roboflow may be deployed by yourself {hardware}.

For this information, we’re going to deploy our mannequin on an edge gadget. For one of the best efficiency, we advocate deploying on a devoted edge compute gadget reminiscent of an NVIDIA Jetson. For testing, you may deploy the mannequin in your pc.

We first want to put in Inference, a system that permits you to run pc imaginative and prescient fashions by yourself {hardware}. For this information, we may also want to put in supervision, a Python bundle that gives a variety of instruments to be used in working with imaginative and prescient fashions.

To put in the required dependencies, run:

pip set up inferenceWe have to set our API key in the environment. We are going to use this API key to authenticate with Roboflow. Discover ways to retrieve your API key.

When you’ve got retrieved your API key, run the next command:

export ROBOFLOW_API_KEY=”key”The place “key” is your API key.

Subsequent, create a brand new Python file and add the next code:

from inference import get_roboflow_model

import supervision as sv

import cv2 picture = cv2.imread("picture.jpg") mannequin = get_roboflow_model(model_id="defect-detection-dqcko/4") outcomes = mannequin.infer(picture) labels = [i.class_name for i in results[0].predictions]

detections = sv.Detections.from_roboflow(outcomes[0].dict(by_alias=True, exclude_none=True)) bounding_box_annotator = sv.BoundingBoxAnnotator()

label_annotator = sv.LabelAnnotator() annotated_image = bounding_box_annotator.annotate( scene=picture, detections=detections)

annotated_image = label_annotator.annotate( scene=annotated_image, detections=detections, labels=labels) sv.plot_image(annotated_image)This code will run our mannequin on a picture known as “picture.jpg”. Substitute the identify “picture.jpg” with the file on which you wish to run your mannequin. Then, the outcomes from inference might be displayed in an interactive window for analysis.

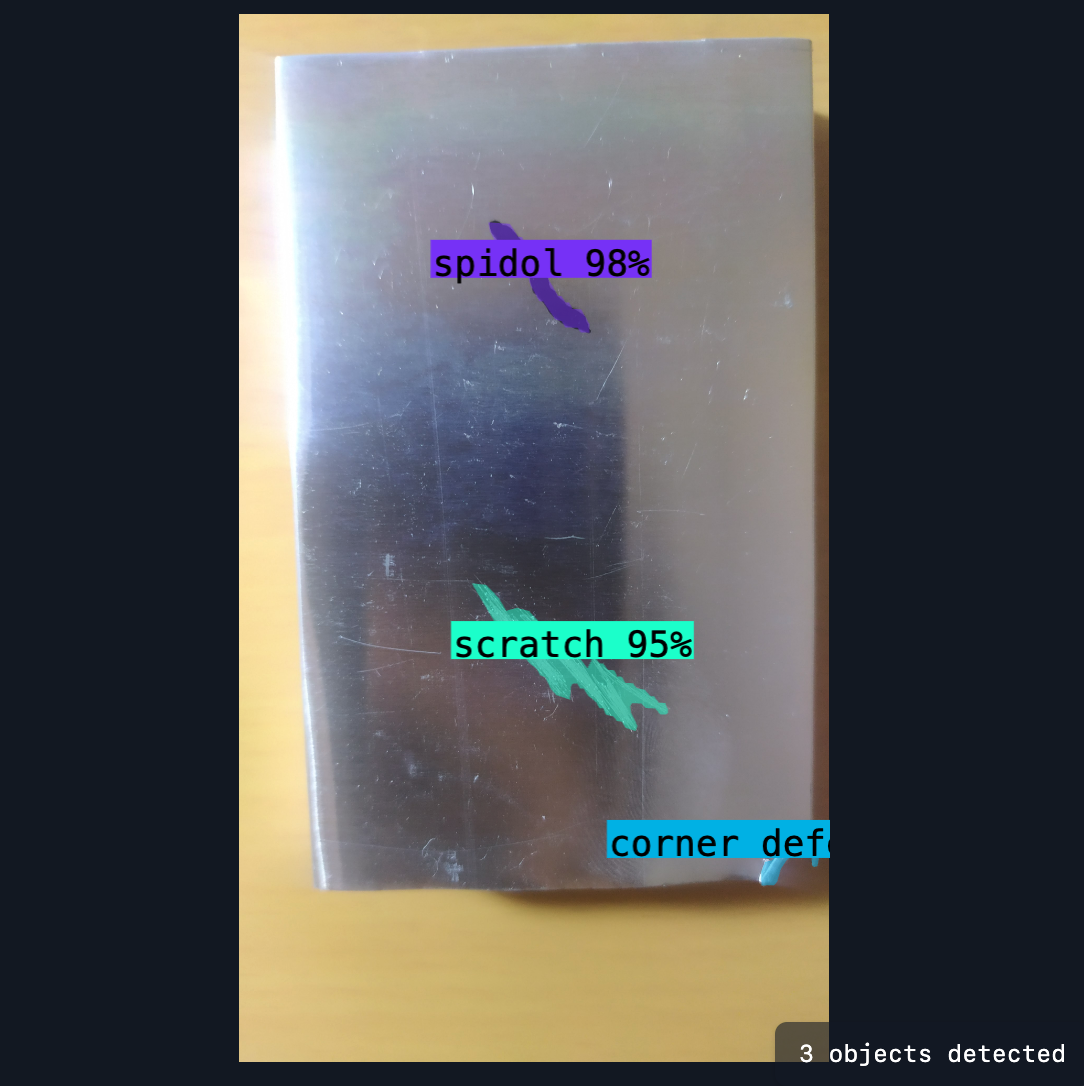

Right here is the results of working our script on an instance picture with a steel defect current:

Our mannequin efficiently recognized the presence of a floor steel defect.

Subsequent Steps: Coaching a Customized Mannequin and Integration into MES Methods

Above, we demonstrated easy methods to use a pre-trained mannequin to determine floor steel defects. With that stated, we advocate coaching a customized mannequin for a manufacturing system utilizing your individual knowledge. This can permit you to guarantee your system identifies as many cases of defects as potential. The extra consultant the pictures on which a mannequin is skilled are of the atmosphere by which your mannequin might be deployed, the higher your mannequin will carry out.

The steps of constructing a imaginative and prescient mannequin are as follows:

- Acquire photos.

- Annotate defects in every picture utilizing a labeling instrument.

- Generate a dataset.

- Prepare a mannequin.

- Deploy your mannequin.

You’ll be able to prepare the primary model of a imaginative and prescient mannequin in a day. To get began, seek advice from the Roboflow Getting Began information.

After you have skilled a customized mannequin, you can begin making use of enterprise logic to the output of the mannequin. For instance, you may seek for defects in a selected nook of an object. You’ll be able to measure the size of scratches or you may monitor the stage of your manufacturing course of the place defects are almost definitely.

The supervision Python bundle gives an intensive suite of utilities to be used in integrating pc imaginative and prescient into your corporation logic. Supervision has instruments for visualizing outcomes from pc imaginative and prescient fashions, counting the period of time an object spends in a zone, counting when objects cross a line, filtering predictions by dimension, and extra.

Should you want help in constructing a imaginative and prescient mannequin to your use case and deploying the mannequin to manufacturing, contact the Roboflow gross sales workforce. The Roboflow workforce works with enterprises reminiscent of Rivian Automotive on constructing sturdy high quality assurance fashions with pc imaginative and prescient fashions.