Juice packing containers want a straw earlier than they are often bundled and despatched for distribution. If a juice field doesn’t have a straw, or if the straw is malformed, the field shouldn’t be match for objective. Customers could be unable to devour the product.

You should use laptop imaginative and prescient to construct a juice field high quality inspection system. Utilizing laptop imaginative and prescient, you possibly can classify pictures of juice packing containers in your meeting line to establish potential defects. Defects may embody a lacking straw, a bent straw, and a straw that has pierced via its packaging.

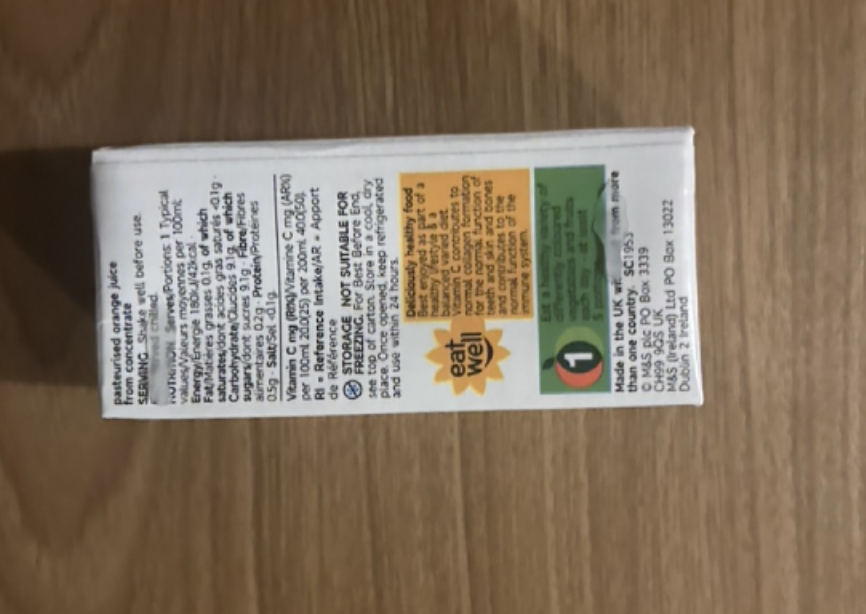

On this information, we’re going to present the way to construct a juice field high quality inspection system. By the top of the information, we may have a system that may confirm the integrity of a juice field. For instance, our system experiences the next carton is lacking a straw:

With out additional ado, let’s get began!

Step #1: Create a Challenge

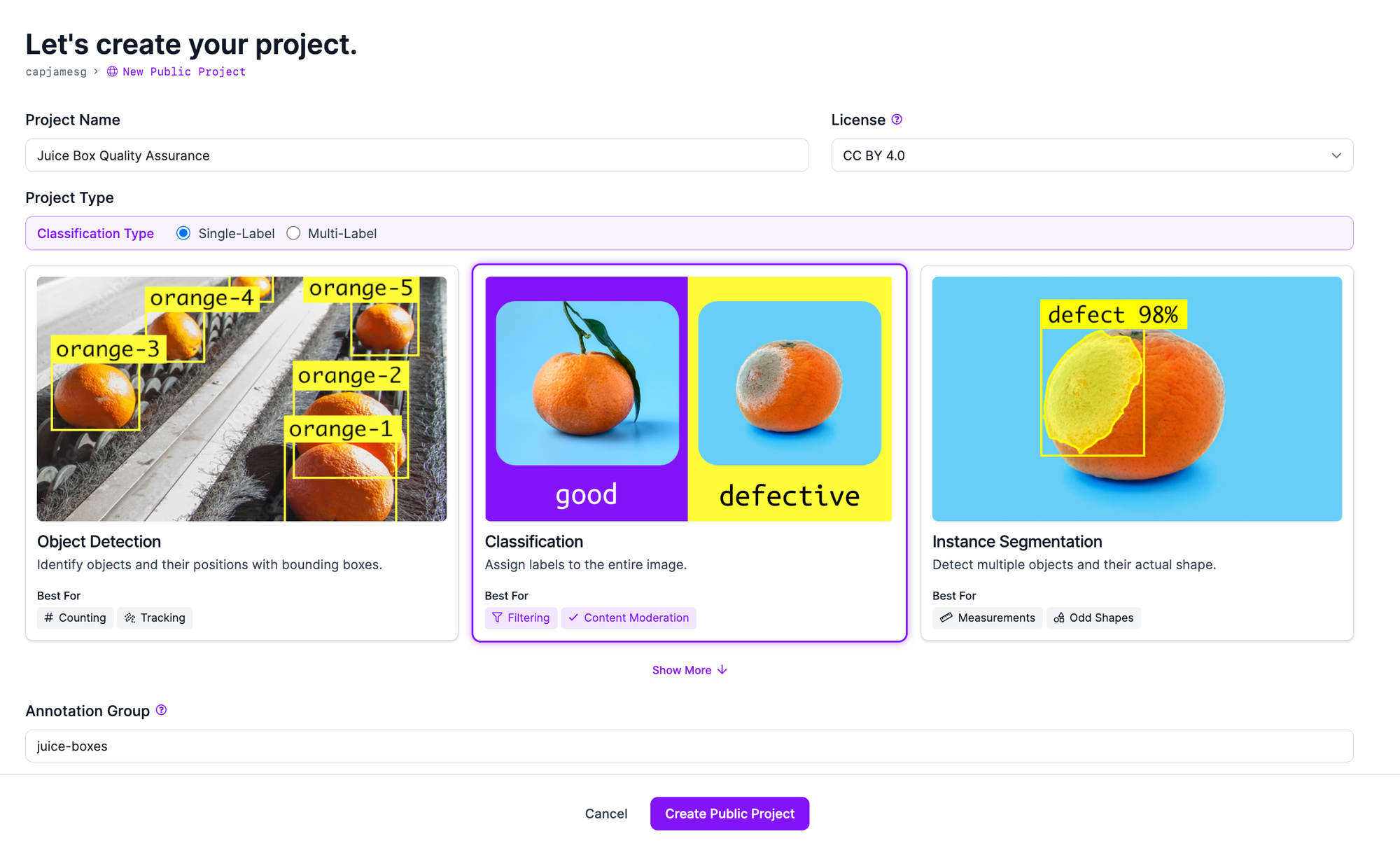

First, create a free Roboflow account. Then, go to your Roboflow dashboard and click on “Create a Challenge”. On this web page, you can be requested to pick out a reputation in your challenge, select a challenge kind, and fill out extra data.

When requested to decide on a challenge kind, choose Classification. It’s because we’re going to classify whether or not a juice field does or doesn’t have a defect current. We need not know the place the defect is, the specialty of object detection and segmentation fashions. Study extra about picture classification in our complete information.

Click on “Create Challenge” on the backside of the web page to create your challenge.

Step #2: Add Juice Field Information

To construct a pc imaginative and prescient system, you want pictures that present each acceptable and faulty merchandise. You may label these pictures to show the system the way to establish totally different defects of curiosity. For instance, you may wish to acquire pictures the place a field has a lacking straw or the place a straw is bent contained in the packaging.

We advocate gathering 50-100 pictures. Of those pictures, it’s best to have not less than 10 pictures of every defect you wish to classify. It’s best to acquire pictures out of your meeting line for optimum efficiency. Laptop imaginative and prescient methods work finest when skilled on pictures consultant of the atmosphere and product on which the system can be used.

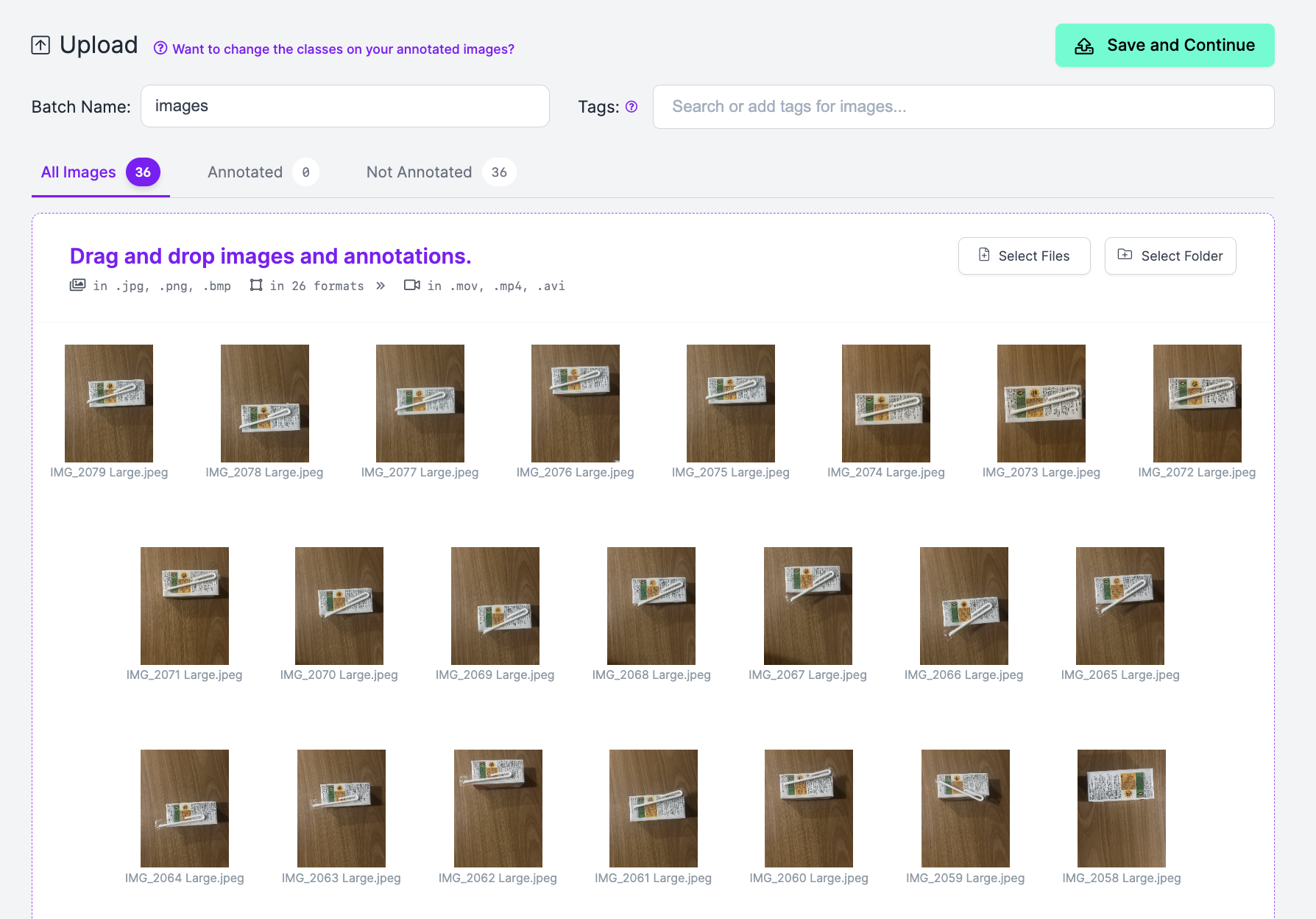

After you have gathered pictures, you possibly can add them to Roboflow.

If you add your pictures, they are going to be processed. Then, a button will seem that claims “Save and Proceed”. Click on this button to add your pictures to Roboflow.

Step #3: Label Juice Field Pictures

Subsequent, we have to label pictures that we’ll use to coach a imaginative and prescient mannequin to guarantee the standard of juice packing containers. To start out labeling pictures, click on Annotate within the left sidebar of your Roboflow challenge. Click on on a picture to start out labeling.

To label a picture, kind in a label for the picture within the labeling device. Keep in mind to make use of constant, descriptive labels as you label your dataset.

For this information, we are going to use 4 labels:

- Pierced straw

- Free straw

- Lacking straw

- Correctly packaged straw (

acceptable)

Assign a single label for every picture. Label each picture in your dataset.

Step #4: Generate a Dataset Model

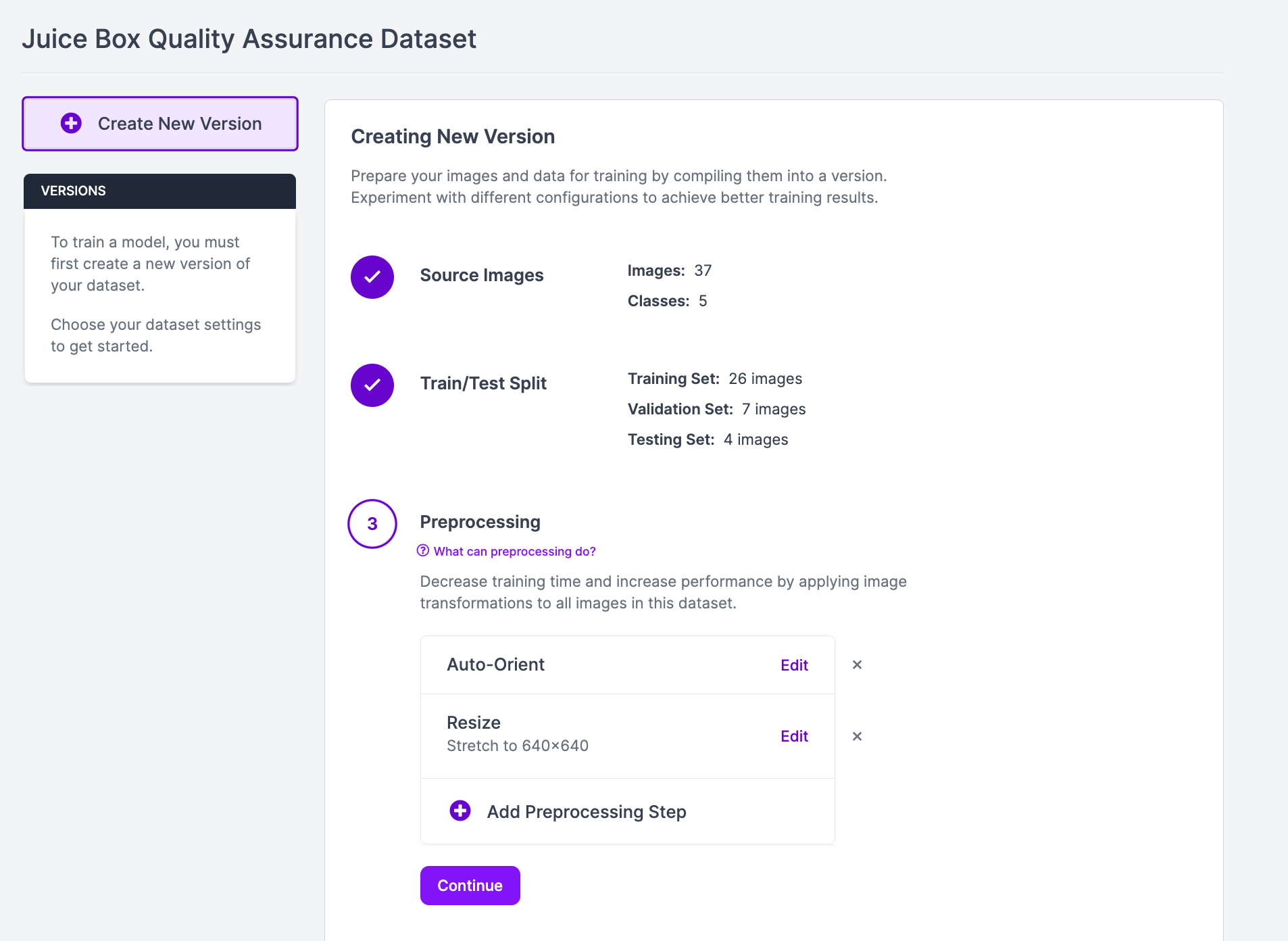

After you have labeled your knowledge, you possibly can generate a dataset model. A dataset model is a snapshot of your dataset that you should use to coach your juice field high quality mannequin.

Click on “Generate” within the Roboflow sidebar. On this web page, you possibly can configure your dataset model. You may apply preprocessing and augmentation steps to assist put together your mannequin for coaching and increase mannequin efficiency, respectively.

For this information, we advocate leaving the preprocessing and augmentation steps as their default values. It’s simpler so as to add augmentation steps when you know the way your mannequin performs utilizing your uncooked knowledge with out augmentation. In case your mannequin performs effectively with out augmentation, it’s possible you’ll not want so as to add augmentations. In case your mannequin struggles with out augmentation, it’s a signal it’s possible you’ll want extra pictures.

To be taught extra about picture preprocessing and augmentation, consult with the Roboflow preprocessing and augmentation information.

Click on “Create” on the backside of the web page to generate your dataset model. The period of time this course of will take relies on the variety of pictures you’ve gotten in your dataset and what augmentations you’ve gotten utilized. After your dataset has been generated, you can be taken to the web page on which you can begin coaching your mannequin.

Step #5: Prepare a Juice Field Inspection Mannequin

To coach your mannequin, click on the “Prepare with Roboflow” button in your dataset model web page.

A pop up will seem in which you’ll be able to configure your mannequin coaching job. On step one, choose “Quick” coaching. On the second step, choose the “Prepare from Public Checkpoint” possibility and practice from the Microsoft COCO mannequin.

After you have configured your coaching job, your mannequin coaching can be assigned to a server. You’ll obtain an estimate that states roughly how lengthy we predict it would take in your mannequin to coach.

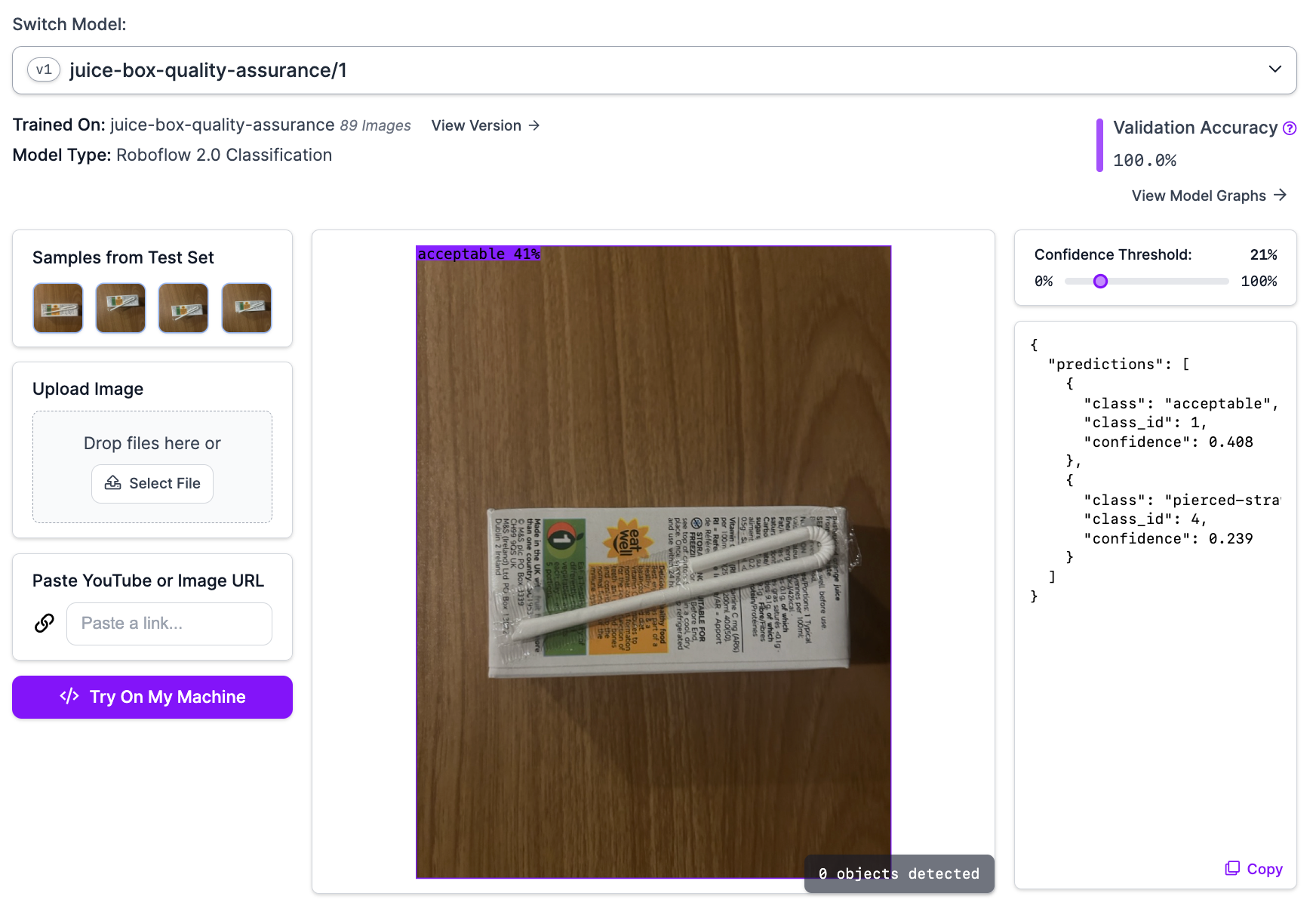

As soon as your mannequin has skilled, you possibly can check it in your browser utilizing the Visualize web page, accessible from the sidebar of your challenge within the Roboflow dashboard.

Right here is an instance of our mannequin working on a picture:

The mannequin efficiently recognized that the field is appropriate.

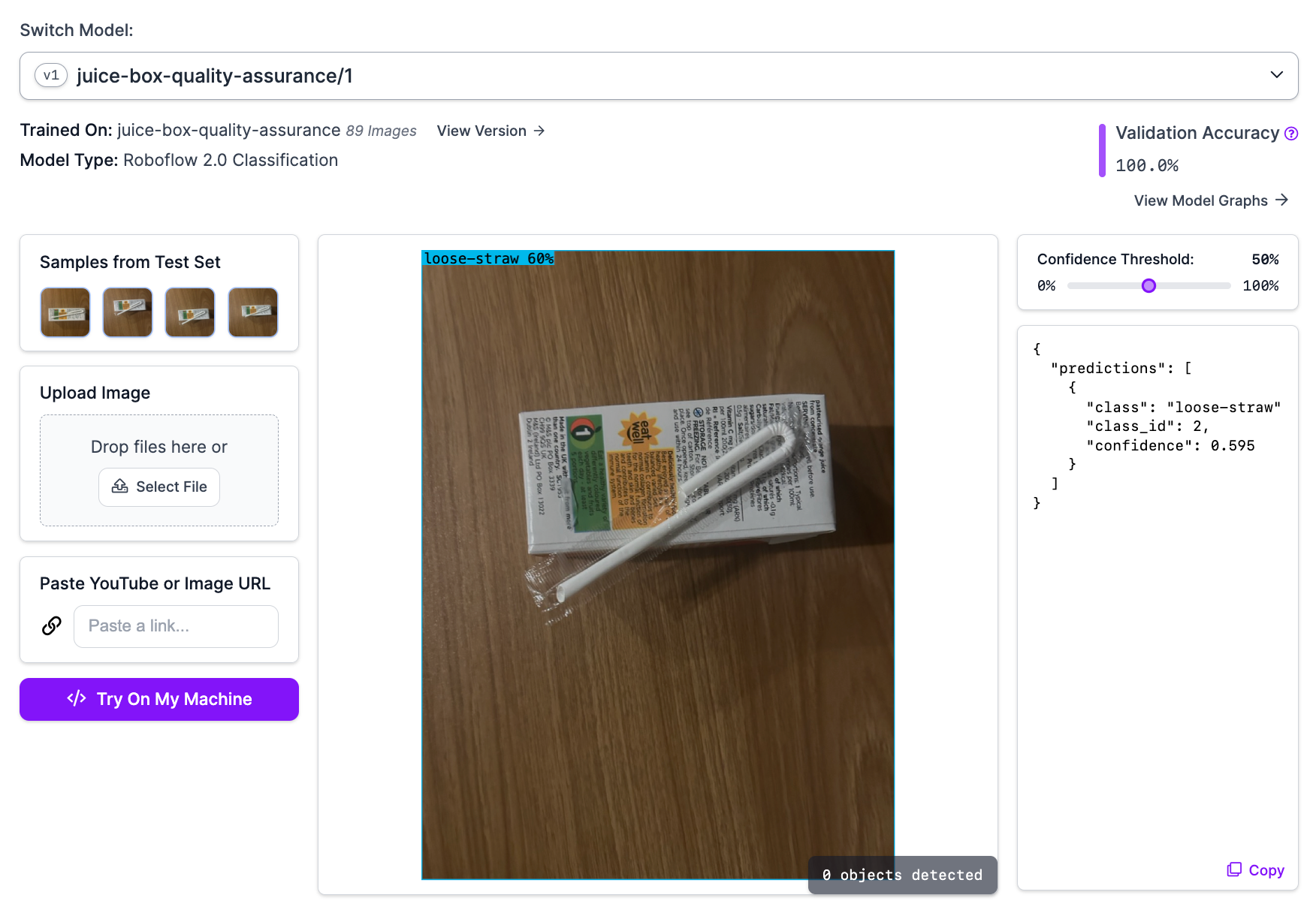

When introduced with a field with a unfastened straw, the mannequin identifies the defect:

Step #6: Deploy the Juice Bottle Inspection System

You may deploy your juice field high quality inspection system to your meeting line utilizing Roboflow Inference. Inference is high-performance software program designed for working laptop imaginative and prescient fashions. You may run imaginative and prescient fashions in actual time over digital camera and RTSP streams with Inference. You may as well run inference on pictures.

For this information, we are going to run inference on a digital camera stream.

To get began, we have to set up Inference and supervision. The supervision Python bundle supplies utilities we are able to use to work with predictions from our mannequin. To put in these dependencies, run the next command

pip set up inference supervisionWith the required dependencies prepared, we are able to begin to deploy our mannequin.

Create new Python file and add the next code:

from inference import get_roboflow_model

import supervision as sv

import cv2 picture = cv2.imread("juice.png") mannequin = get_roboflow_model(model_id="juice-box-quality-assurance/1") outcomes = mannequin.infer(picture) print(outcomes[0].predictions[0].class_name)Above, change juice-box-inspection/1 with the mannequin ID related along with your Roboflow challenge. Discover ways to retrieve your mannequin ID.

This code will run the classification mannequin on a picture. The outcomes can be exhibited to your display, interactively.

Let’s run our code on the next picture:

Our code returns the classification no-straw.

Our system appropriately classifies when a juice field straw is unbroken versus when a straw is lacking or broken.

You may join this method to your individual enterprise logic. For instance, you possibly can robotically reject merchandise with lacking straws and transfer them to the straw attachment technique of your meeting line. You may monitor the incidence charges of defects over time, too.

Conclusion

You may construct a juice field high quality inspection system with laptop imaginative and prescient. On this information, we walked via the way to construct a classification system that identifies whether or not a field has a straw, is lacking a straw, or has a faulty straw.

To construct this method, we gathered pictures, labeled them in Roboflow, skilled a classification mannequin, then deployed our system on a webcam utilizing Roboflow Inference.

To be taught extra about constructing industrial inspection methods with laptop imaginative and prescient, contact the Roboflow gross sales staff. The Roboflow gross sales staff are specialists in architecting options to establish defects on meeting traces.