Within the metal manufacturing business, precision, security, and effectivity are paramount. Pc imaginative and prescient affords revolutionary options to deal with these essential wants, and one such development is laptop imaginative and prescient. Roboflow helps a number of Fortune 50 metal producers to automate course of stream.

This weblog put up explores how customized laptop imaginative and prescient fashions assist metal producers, specializing in two key use instances: (1) metal ladle thermal hotspot detection and (2) coil defect detection.

Metal Ladle Thermal Hotspot Detection

In metal manufacturing, the ladle is an important element used to move and pour molten metal. Sustaining the integrity of the ladle is crucial to stop accidents and guarantee environment friendly operations. One of many important dangers is the event of thermal hotspots, which may result in ladle failure and catastrophic spills of molten metallic.

oboflow’s laptop imaginative and prescient expertise could be deployed to repeatedly monitor the ladle for thermal anomalies. By integrating infrared cameras and superior picture processing algorithms, Roboflow’s answer can detect hotspots in real-time. Here is the way it works:

- Information Acquisition: Infrared cameras seize thermal photos of the ladle’s floor.

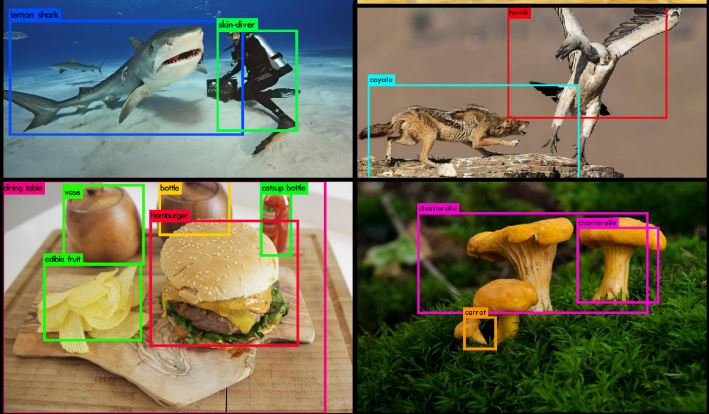

- Object Detection: Information is fed by a customized Roboflow object detection mannequin detecting ladle hotspots and studying

- Alert System: When a thermal hotspot is detected, the system can set off alerts for quick motion, stopping potential ladle failures.

With laptop imaginative and prescient, you may allow:

- Improved Security: Early detection of hotspots reduces the danger of accidents and enhances employee security.

- Prolonged Tools Life: Well timed upkeep and repairs could be carried out earlier than extreme harm happens, extending the lifespan of the ladle.

- Operational Effectivity: Minimizing unplanned downtime and interruptions ensures an environment friendly manufacturing course of.

Right here’s the mannequin in motion detecting hotspots on a FLIR thermal digital camera:

Coil Defect Detection

Metal coils are giant, steady rolls of metal which have been processed and fashioned right into a coiled form. Detecting defects and correct alignment in these coils early within the manufacturing course of is important to keep up product high quality and cut back waste.

Roboflow’s laptop imaginative and prescient fashions examine metal coils for the next:

- Automated Visible Inspection: Mechanically detect floor scratches, dents, in addition to alignment and warping for real-time andon alerts.

- Automated Stock Tracing: Combine with stock administration software program, offering real-time updates on inventory ranges, places, and actions of metal coils.

With laptop imaginative and prescient, you may allow:

- Enhanced High quality Management: Automated and correct defect detection ensures solely high-quality WIP strikes ahead by manufacturing.

- Improved Traceability: Detailed information of every coil’s historical past, together with manufacturing particulars and motion, improve traceability and accountability.

- Elevated Productiveness: Automated inspection processes enhance operational capability and cut back labor hours spent on guide inspection, resulting in increased throughput.

Right here’s a coil counting mannequin on Roboflow Universe (hyperlink).

How Do We Construct in Roboflow?

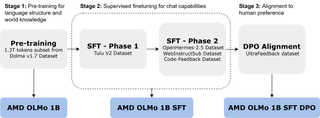

You don’t must be an professional in AI/ML, nor coding expertise to construct and deploy a customized laptop imaginative and prescient mannequin with Roboflow. Highlighting the three principal tiers to constructing a pc imaginative and prescient mannequin with Roboflow: (1) Information, (2) Fashions, and (3) Deployment.

Information Add

Start by importing knowledge (video or photos) of the objects we try to detect ie Metal Coils.

Observe: The mannequin efficiency straight displays the standard of the information. Good knowledge in, good knowledge out.

Labeling Information

As soon as the information is uploaded, the pictures should be labeled, to “educate” the AI mannequin what to detect – these are our courses.

Roboflow affords a set of labeling instruments, like Sensible Polygon instrument to rapidly phase courses. Right here’s the demonstration, labeling metal coils:

Coaching

As soon as the dataset of labeled photos is confirmed, a mannequin model is then created and educated.

Roboflow affords coaching credit to customers in an effort to expedite mannequin coaching on the click on of a button

Deployment

Since Roboflow is {hardware} agnostic, customers are usually not tied down by anybody {hardware} line. Customers have the choice to deploy through Roboflow API, Self-hosted API, or a devoted Software program Developer Kits (SDK), together with an internet browser or Apple iOS.

See what deployment greatest works for you at Roboflow.com/deploy!

Roboflow’s laptop imaginative and prescient options supply metal producers highly effective instruments to reinforce security, enhance product high quality, and optimize effectivity. By leveraging superior imaging applied sciences and machine studying, producers can detect thermal hotspots in metal ladles and establish defects in metal coils with unprecedented accuracy and reliability.