Earlier than bottles might be packaged for distribution, inspections should be run to guarantee the integrity of the bottle cap. If a bottle cap just isn’t correctly sealed, it should be rejected earlier than continuing to packaging and distribution.

Pc imaginative and prescient can be utilized to determine whether or not a cap is or just isn’t correctly sealed, and examine whether or not there may be or just isn’t a cap current on a bottle.

On this information, we’re going to stroll by how you can construct a bottle cap inspection system that verifies the integrity of a bottle cap. By the tip of this information, we may have a system that may routinely determine whether or not a cap is sealed. Right here is an instance of the system working:

With out additional ado, let’s get began!

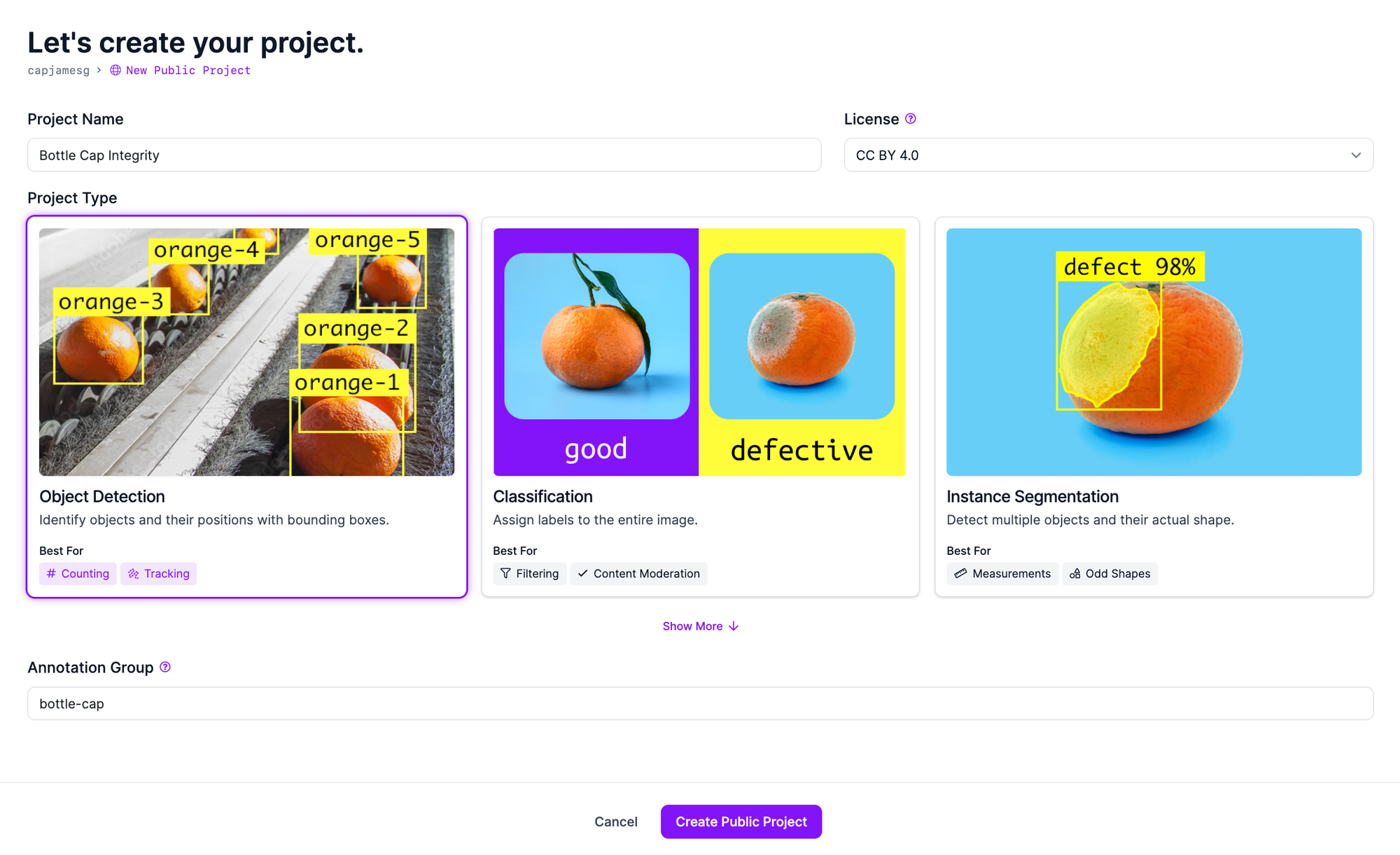

Step #1: Create a Challenge

First, create a free Roboflow account. Then, go to your Roboflow dashboard. Click on the “Create a Challenge” web page to create a venture. You’ll be taken to a web page the place you’ll be requested to configure your venture.

Select a reputation in your venture. Choose “Object Detection” as your venture sort. After you have crammed out the required fields, click on “Create Challenge”.

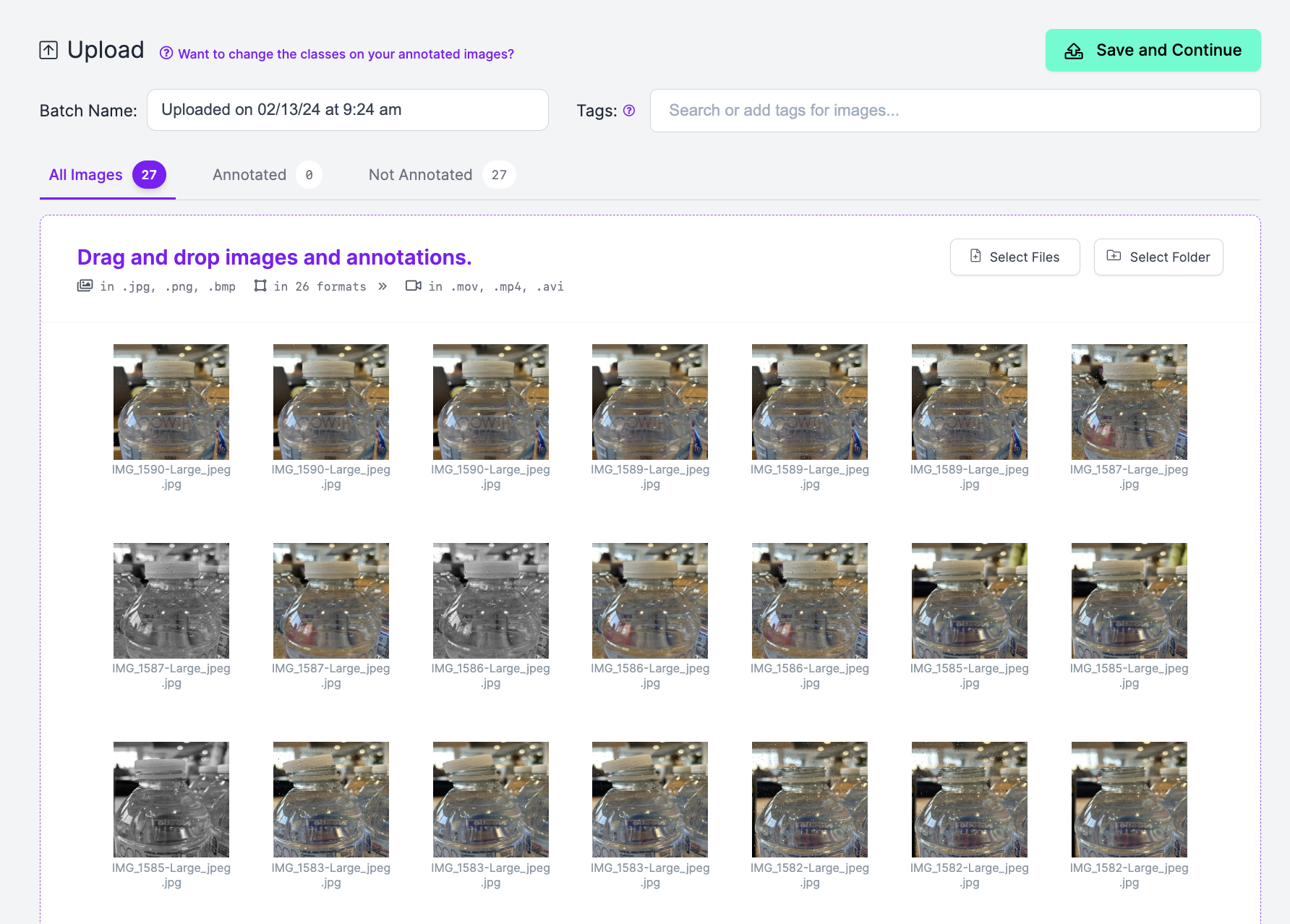

Step #2: Add Bottle Cap Information

To construct a pc imaginative and prescient system, it’s good to label photographs with objects of curiosity. We have to practice our system to determine whether or not a bottle cap is or just isn’t correctly sealed. For that, we are going to want photographs that present a bottle cap that’s each sealed, not correctly sealed, and lacking. For optimum efficiency, we suggest gathering photographs of bottle caps out of your meeting line.

Listed below are a couple of instance photographs of bottles with totally different caps:

Left: A bottle with an unsealed cap. Proper: A bottle with a correctly sealed cap.

We suggest accumulating 20-50 photographs that present all kinds of defects you wish to determine in your first mannequin. For this instance, we now have collected photographs that present:

- A sealed cap;

- A free cap, and;

- A lacking cap.

After you have created a venture, you’ll be taken to a web page on which you’ll be able to add your knowledge. To add knowledge, drag photographs onto the add knowledge web page. Your photographs will likely be processed in your browser. Then, click on “Save and Proceed” to add your photographs.

Step #3: Label Bottle Cap Photographs

You should annotate your photographs to coach your mannequin to determine free and sealed caps. This course of is often known as labeling.

You’ll be able to annotate your photographs with Roboflow Annotate. To get began, click on Annotate within the left sidebar. Then, choose a picture to annotate. You’ll be taken to the labeling interface the place you possibly can label your knowledge.

To create a label, first press “b” in your keyboard or click on the field software in the appropriate sidebar. It will toggle the bounding field software to be used in drawing object detection labels.

Click on the place you wish to begin drawing your label on the picture then drag your cursor across the object of curiosity. When you may have surrounded the area of curiosity – a full or free cap – with a field, cease clicking. You’ll be able to then choose a category to assign to your label.

Label all bottle caps within the photographs you uploaded to Roboflow.

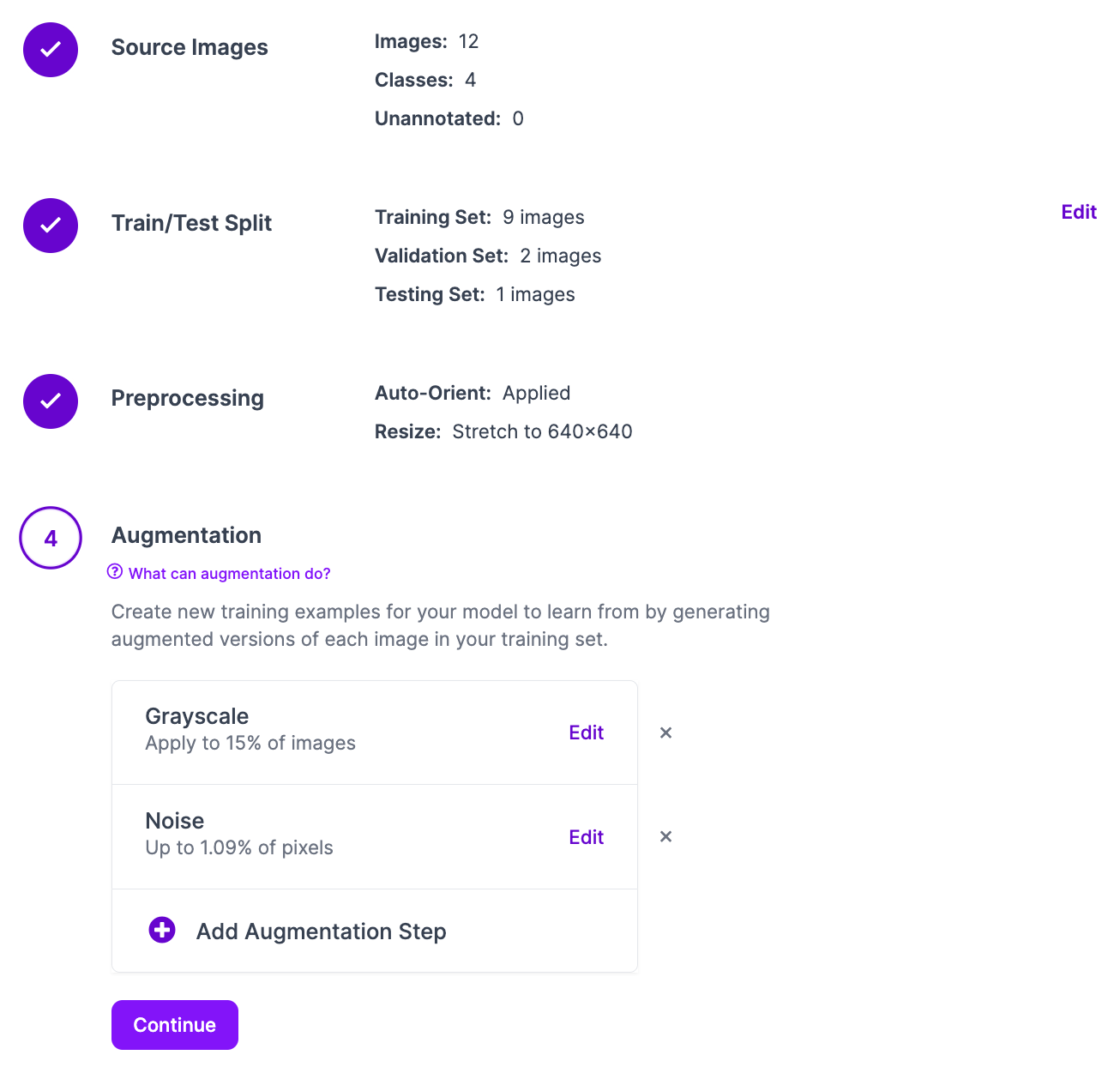

Step #4: Generate a Dataset Model

With the entire photographs labeled, you possibly can generate a dataset model. A dataset model is a snapshot of your labeled photographs. You’ll be able to apply preprocessing and augmentation steps to organize your mannequin for coaching and enhance mannequin efficiency, respectively.

To generate a dataset, click on “Generate” within the sidebar. You’ll be taken to a web page on which you’ll be able to configure your dataset model.

In your first dataset model, we suggest leaving the preprocessing steps because the default. We suggest making use of the next augmentations in your first model:

- Greyscale

- Noise (as much as 1% of pixels)

You need to solely apply a greyscale augmentation if bottle cap colour doesn’t matter. If it’s good to confirm the colour of a bottle cap, don’t apply a greyscale augmentation.

Click on the “Create” button beneath the “Generate” step on the backside of the web page to create your dataset model.

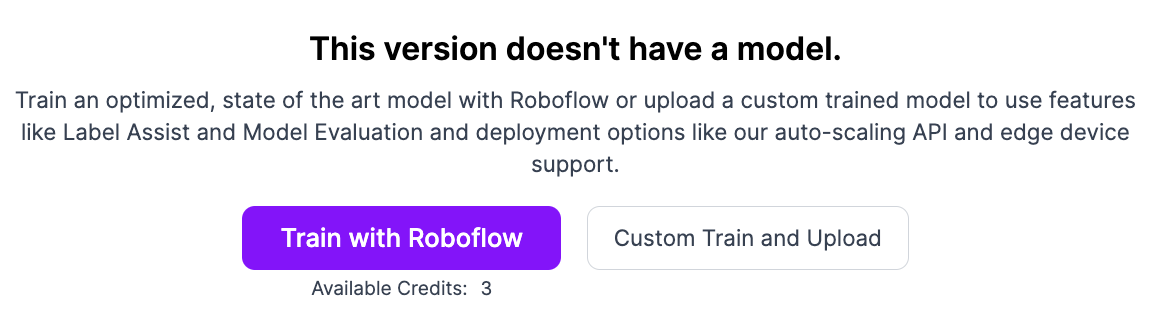

Step #5: Practice a Bottle Cap Inspection Mannequin

With a dataset prepared, you possibly can practice a mannequin to examine bottle caps.

To begin coaching a mannequin, click on the Practice with Roboflow button in your dataset web page.

A pop up will seem in which you’ll be able to configure your mannequin coaching job. From this pop up, choose “Quick” coaching. Then, choose the choice to coach from the Microsoft COCO Checkpoint. After you have configured your coaching job, an estimate will seem that reveals roughly how lengthy it ought to take to coach your mannequin.

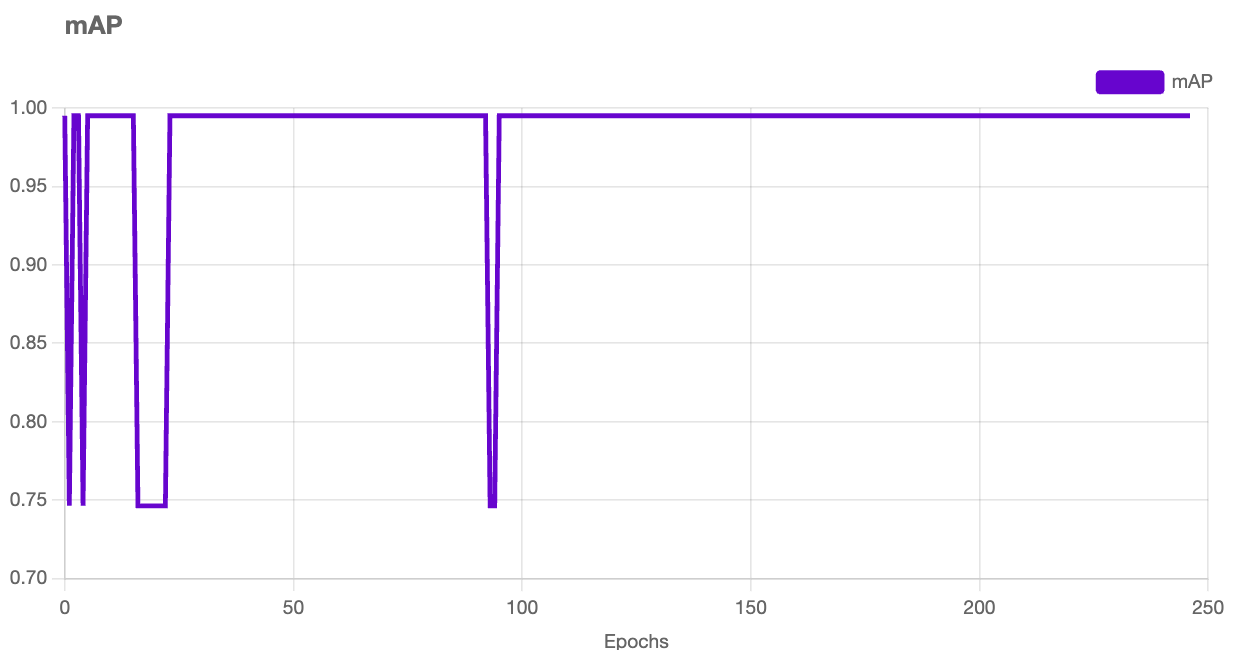

You’ll be able to monitor your coaching job in actual time out of your dataset web page. As soon as your coaching job has been allotted to a machine, a graph will seem that reveals the efficiency of your mannequin because it trains.

You’ll obtain an e mail as soon as your mannequin has skilled.

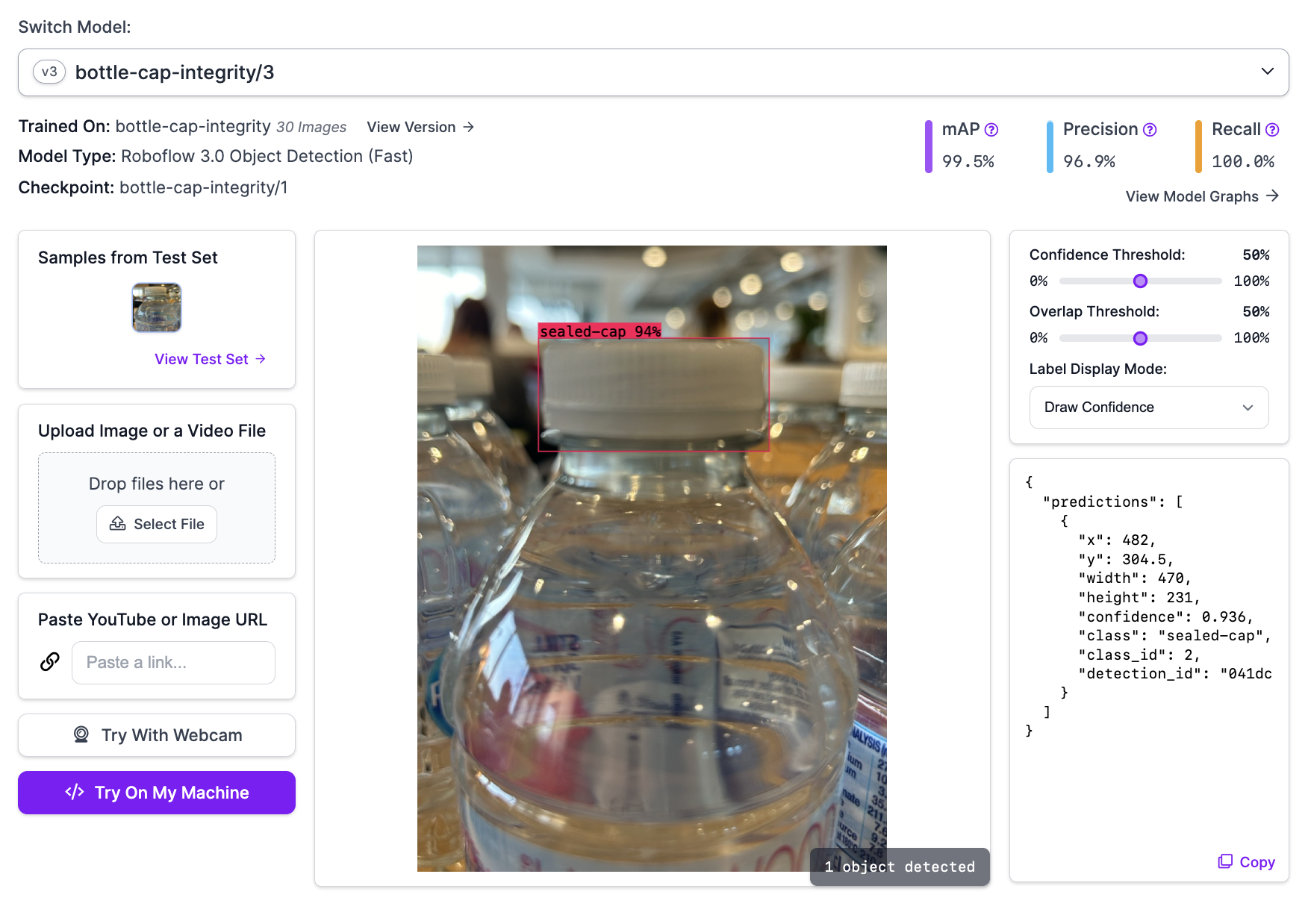

When your mannequin has completed coaching, you possibly can check it from the .Visualize tab accessible within the sidebar of your venture.

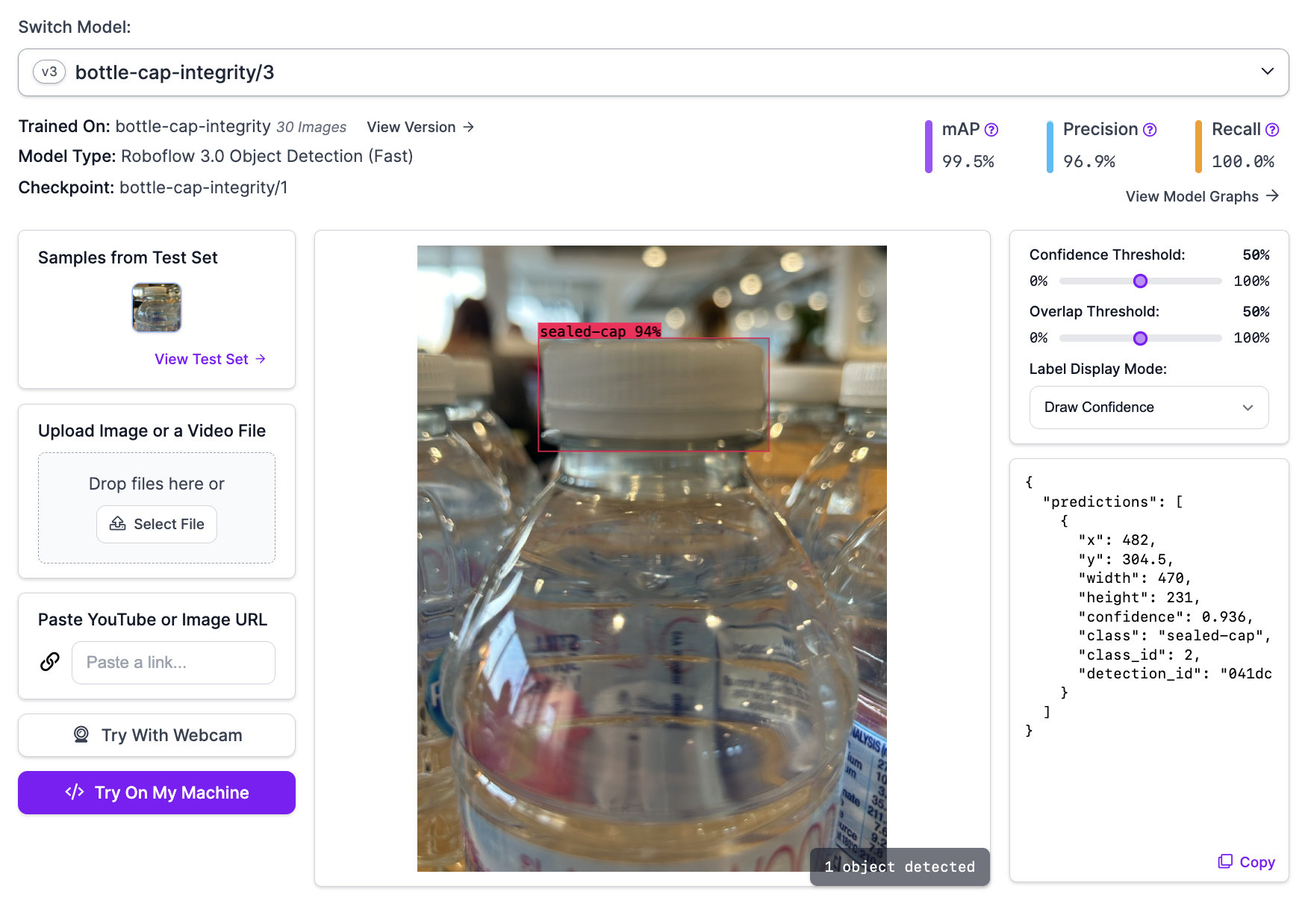

Right here is an instance of our mannequin working to determine a sealed cap:

Our mannequin efficiently recognized {that a} bottle cap is correctly sealed.

Step #6: Deploy the Bottle Cap Inspection Mannequin

With a mannequin prepared, you possibly can deploy it by yourself {hardware} utilizing Roboflow Inference. Roboflow Inference is high-performance software program that permits you to run pc imaginative and prescient fashions on photographs, movies, reside digicam streams, and RTSP streams.

For this information, we are going to check our mannequin on a picture. Confer with the Inference documentation to discover ways to deploy a mannequin on a digicam stream in actual time.

To get began, we have to set up Inference. We additionally want to put in supervision, a Python package deal with utilities for working with pc imaginative and prescient fashions.

To put in the required dependencies, run the next command:

pip set up inference supervisionSubsequent, it’s good to export your Roboflow API key into your surroundings. To take action, set an surroundings variable known as ROBOFLOW_API_KEY:

export ROBOFLOW_API_KEY="key"Discover ways to retrieve your Roboflow API key.

Subsequent, create a Python file and add the next code:

from inference import get_roboflow_model

import supervision as sv

import cv2 picture = cv2.imread("picture.jpg") mannequin = get_roboflow_model(model_id="bottle-cap-integrity/3") outcomes = mannequin.infer(picture) labels = [i.class_name for i in results[0].predictions]

detections = sv.Detections.from_inference(outcomes[0].dict(by_alias=True, exclude_none=True)) bounding_box_annotator = sv.BoundingBoxAnnotator()

label_annotator = sv.LabelAnnotator() annotated_image = bounding_box_annotator.annotate(

scene=picture, detections=detections)

annotated_image = label_annotator.annotate(

scene=annotated_image, detections=detections, labels=labels) sv.plot_image(annotated_image)Above, substitute bottle-cap-integrity/3 along with your mannequin ID and model quantity. Discover ways to retrieve your mannequin ID and model quantity. Change picture.jpg with the title of the picture on which you wish to run inference.

When this code first runs, our mannequin will likely be downloaded to our machine. This will take a couple of moments. Then, our mannequin will run on a picture. The outcomes from our mannequin will likely be plotted onto our picture interactively, permitting us to ensure our mannequin is working as anticipated.

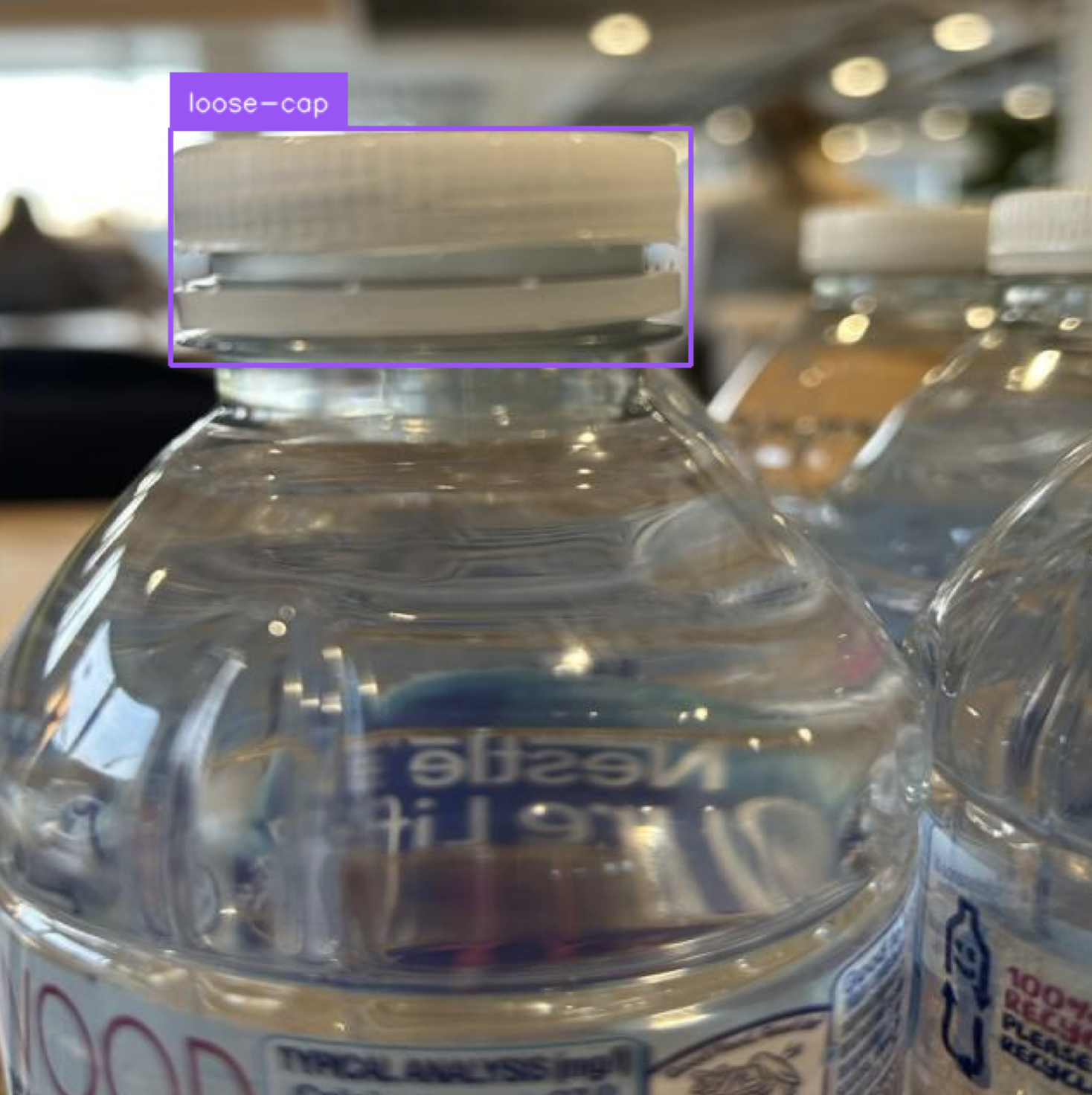

Let’s run the code on a picture the place a bottle cap just isn’t correctly sealed. Listed below are the outcomes:

Our mannequin efficiently recognized that the bottle cap was not correctly sealed.

You’ll be able to combine this technique into your enterprise logic. For instance, you possibly can routinely reject bottles whose caps should not correctly sealed. You’ll be able to depend the variety of bottles whose caps weren’t correctly sealed or have been lacking every day to observe defect charges over time.

Conclusion

On this information, we constructed a bottle cap inspection system with pc imaginative and prescient. Our system was skilled to determine correctly sealed bottle caps, bottle caps that aren’t correctly sealed, and bottles which can be lacking caps. To do that, we gathered photographs exhibiting these bottle cap statuses, labeled them, then skilled a imaginative and prescient mannequin.

We then deployed our system onto our personal {hardware} utilizing Roboflow Inference.

Be taught extra about figuring out the presence of bottles in multipacks earlier than they’re packaged, confer with the Roboflow lacking merchandise inspection information.

To be taught extra about constructing industrial inspection methods with pc imaginative and prescient, contact the Roboflow gross sales staff. The Roboflow gross sales staff are specialists in architecting options to determine defects on meeting traces.