Welding is likely one of the most crucial processes concerned within the world manufacturing trade, important for becoming a member of and fusing materials to create sturdy and dependable constructions. The standard and integrity of the weld may be ensured by monitoring the weld penetration into the mum or dad materials. As a consequence of its dynamic nature and excessive temperature, straight observing the welded joint, particularly the liquid-solid interface, may be difficult.

In previous, sensors have been used to collect welding knowledge from the gas-liquid interface, offering operators with an oblique inference of the penetration website.

Welding may be an inherently complicated course of. Attaining constant and exact monitoring of that welding course of entails sooner or later, detecting, measuring and monitoring the weld arc and soften pool throughout an energetic weld. Various materials metallurgy, fluctuating enter energy parameters, shielding gasoline composition and wire high quality and placement are simply a few of the variables that may make correct monitoring tough. To beat these challenges, superior applied sciences like thermal imaging and real-time knowledge analytics are revolutionizing the welding subject and empowering welders to attain unparalleled understanding of their processes.

How Superior Monitoring Applied sciences Can Enhance Welding Processes

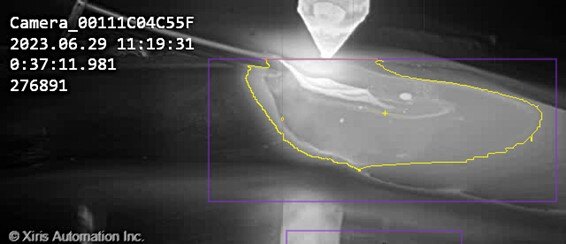

Thermal imaging can present an entire new degree of understanding the welding course of. By combining a superb high quality thermal picture with applicable machine imaginative and prescient instruments, weld options such because the soften pool, torch tip high quality and cooling weld bead may be imaged and analysed successfully regardless of the variations in mild and warmth current in a typical welding setting. Machine imaginative and prescient know-how allows function and knowledge extraction from a picture in order that form evaluation, edge detection, sample matching and temperature evaluation can used to characterize the options of the weld.

For instance, with machine imaginative and prescient, the soften pool boundary may be recognized by segmenting its temperature traits from the remainder of the welding scene. As soon as segmented, particular geometric parameters of the ensuing soften pool area, corresponding to form, space and place may be measured and tracked because the soften pool strikes or morphs its form. That is significantly helpful when the soften pool can nonetheless be detected underneath complicated conditions when components corresponding to confined house, restricted lighting and digicam angles differ.

|

Fig. 1: Soften Pool of a Thermal Picture Segmented with a Blob Software (Xiris)

Using Machine Imaginative and prescient and AI for Smarter Welding Options

Regardless of important advances in utilizing classical machine imaginative and prescient for welding processes, a number of challenges persist. The preliminary step in utilizing classical machine imaginative and prescient to determine the item in a welding scene that must be tracked, sometimes the arc, the seam and the soften pool, may be difficult as the sunshine depth of all these options could also be related sufficient to trigger fewer or higher pixels to be categorized as a part of every object.

In machine imaginative and prescient, a number of algorithms work collectively to detect and monitor objects in a video. This strategy is efficient generally, however within the case of a soften pool, the approach struggles to detect the ellipsoidal form resulting from inadequate color or distinction differentiation between the puddle and the encircling steel. To deal with this, extra strategies corresponding to edge-detection, noise discount and picture averaging may be employed to trace and document the soften pool successfully.

Such machine imaginative and prescient strategies can enhance the item monitoring, making it extra exact, even when the item is partially or totally obscured, simplifying measurement after figuring out the puddle.

Nevertheless, in sure conditions, higher strategies are wanted to search out the extent of a soften pool whose boundary is difficult to search out. That is the place AI is available in.

AI-Pushed Insights for Enhanced Weld Monitoring and Parameter Optimization

Conventional Object detection processes depend on figuring out variations in brightness ranges between an object and its background, or discovering edges of the item the place they exist.

The high-temperature setting of welding additional complicates the direct remark of the liquid-solid interface with pc imaginative and prescient. To beat this, thermal cameras are used to gather 2D pictures of the temperature of a scene. With such pictures, object segmentation is unquestionably simpler than with solely seen mild imaging.

Nevertheless, even one of the best classical machine imaginative and prescient strategies are usually not capable of phase all options on a regular basis.

AI (Synthetic Intelligence) strategies may be employed to boost the standard of the segmentation of the scene for higher knowledge extraction. As well as, different top-side sensors can be utilized to gather uncooked knowledge from the weld interface.

This oblique technique entails figuring out phenomena that correlate with penetration state variables, corresponding to incomplete penetration, penetration depth, and back-side bead width.

To boost mannequin predictions utilizing AI, a number of knowledge sources are required, significantly the place the complicated welding processes, materials properties, temperature variation and different welding parameters are consistently altering. These sources can embody soften pool reflection pictures, energetic pool oscillation pictures, and temperature fields. Integrating and analysing all the knowledge sources with an AI processing engine gives a extra complete and full overview of the welding course of.

.png?width=1380&height=745&name=Melt%20Pool%20Segmentation%20and%20Measurement%20in%20WeldStudio%20(Xiris).png)

|

Case Research: Actual-Time Weld Penetration Monitoring with AI/Deep Studying

Rui Yu et al., from the College of Kentucky, United States carried out a current examine demonstrating the effectiveness of AI/deep learning-based real-time monitoring on weld penetration. The researchers have highlighted the necessity for dynamic adjustment of welding parameters and the issue of real-time in-situ monitoring because of the non-observability of the penetration state throughout the welding course of.

The info set used within the paper was comprised of thermal pictures of the welding course of. These pictures have been processed utilizing deep studying algorithms to determine and monitor the soften pool’s contours and temperature patterns with promising outcomes. This examine underscores the potential of thermal welding cameras in enhancing weld penetration monitoring by superior picture high quality and real-time knowledge processing.

Conclusion: Elevating Weld High quality by Chopping-Edge Monitoring Applied sciences

SWIR thermal digicam know-how, classical machine imaginative and prescient and AI applied sciences are revolutionizing weld accuracy, efficiency, and general high quality. The challenges posed by detecting and monitoring the welding arc and molten puddle underscore the individuality of every machine imaginative and prescient software. Methods which are efficient in a single state of affairs could also be insufficient in one other, highlighting the significance of a complete understanding of varied machine imaginative and prescient algorithms and their particular use instances. By leveraging SWIR thermal digicam know-how and superior temperature sample detection, trendy welding programs can obtain unprecedented ranges of dependable “arc-on” efficiency, guaranteeing high-quality welds and enhancing general productiveness in manufacturing

References

Yu, R., Cao, Y., Chen, H., Ye, Q., & Zhang, Y. (2023). Deep studying primarily based real-time and in-situ monitoring of weld penetration: The place we’re and what’s wanted revolutionary options? Journal of Manufacturing Processes, 93, 15-46.

Keep updated by following us on social media or subscribe to our weblog!

![]()

![]()

![]()

![]()